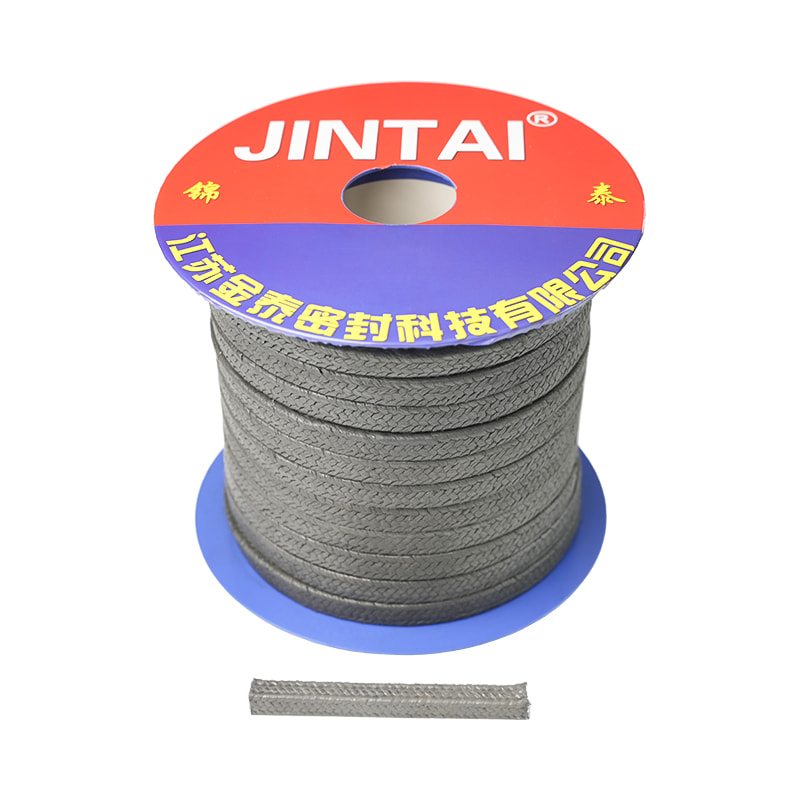

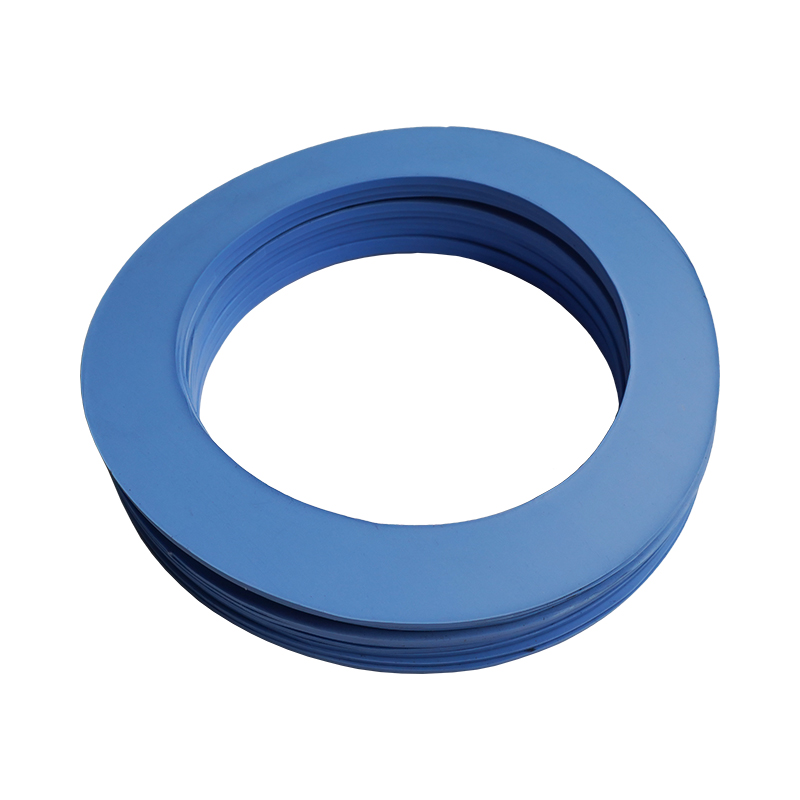

Graphite 304 Stainless Steel Metal Cladding Gasket

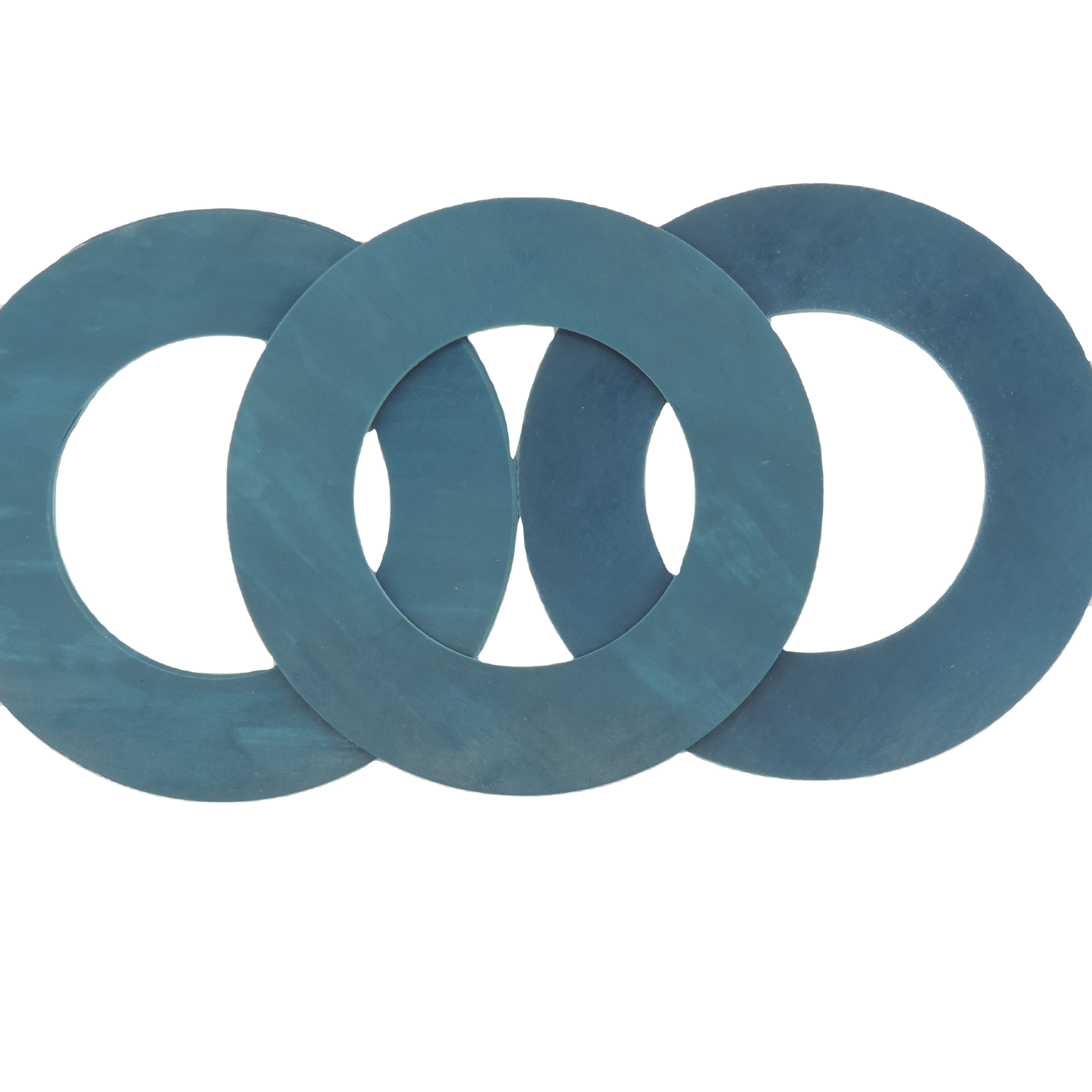

The coated gasket is a product produced by a thin layer of metal-coated soft inorganic sealing filler with high heat resistance. The composite sheet is made of non-metallic materials (flexible graphite, polytetrafluoroethylene, asbestos rubber sheets, ceramic fibers, etc.) on the inside and metal sheets on the outside using a specific cold working process.

High-Temperature Graphite 304 Stainless Steel Gasket for Industrial Piping

Our Graphite 304 Stainless Steel Metal Cladding Gasket is engineered for superior sealing performance in demanding industrial applications. This high-performance gasket combines the exceptional heat resistance of graphite with the durability of 304 stainless steel, making it ideal for extreme temperature and pressure conditions.

- Exceptional Thermal Resistance: Withstands temperatures up to 1000°F (538°C) in oxidizing atmospheres

- Superior Compression: Graphite core provides excellent conformability to flange surfaces

- Corrosion Resistant: 304 stainless steel cladding offers protection against chemical and environmental corrosion

- Reliable Sealing: Maintains tight seals even under thermal cycling and vibration

- Long Service Life: Outperforms traditional gasket materials in durability

Our graphite clad stainless steel gasket is widely used in:

- Oil and gas processing equipment

- Chemical and petrochemical plants

- Power generation systems

- Refinery piping systems

- High-temperature steam applications

- Marine and offshore installations

- Food processing equipment

- Pharmaceutical manufacturing

Why Choose Our 304 Stainless Steel Graphite Gasket?

Unlike standard gaskets, our metal clad graphite gasket offers:

- Enhanced Safety: Prevents leakage in critical applications

- Cost Efficiency: Reduces maintenance and replacement frequency

- Versatility: Suitable for a wide range of media including acids, alkalis, and solvents

- Customization: Available in various thicknesses and diameters to match specific requirements

- Quality Assurance: Manufactured under strict quality control standards

Installation Recommendations

For optimal performance of your 304 stainless steel graphite gasket:

- Ensure flange surfaces are clean and free of imperfections

- Use proper torque values during installation

- Follow industry-standard bolt tightening patterns

- Inspect regularly as part of preventive maintenance programs

- Store in dry conditions before installation

Frequently Asked Questions

Q: Can this gasket be used in food-grade applications?

A: Yes, the 304 stainless steel construction makes it suitable for food processing when properly cleaned.

Q: How does this compare to spiral wound gaskets?

A: Our graphite clad gasket offers better thermal conductivity and typically longer service life in high-temperature applications.

Q: Are custom shapes available?

A: Yes, we can manufacture custom configurations including oval, square, and other non-standard shapes.

Specifications

Model

|

Name |

Profile |

serial number |

|

Single-layer coating type |

|

JINTAI 2700 JINTAI 2701 |

|

Double layer coating |

|

JINTAl 2702 JINTAI 2703 |

|

Wave covered type |

|

JINTAI 2704 |

Material properties

|

Metallic material |

Filler |

Filling material temperature limit |

|

Soft iron |

Graphite |

500℃ |

|

304 SS |

Asbestos free |

250℃ |

|

316 SS |

Asbestos |

500℃ |

|

321 SS |

PTFE |

250℃ |

|

410 SS |

Ceramics 1100℃ Note: Please consult when using temperatures above 500°C. |

|

|

Copper |

||

|

Aluminum |

||

|

MONEL 400 |

||

|

Lead |

||

|

Titanium |

||

|

Nickel 200 |

||

KEEP IN TOUCH

-

In high-utility power generation, the integrity of a steam turbine relies heavily on the performance of its static sealing interfaces. A metal gasket ring is often the first line of defense against ca...

READ MORE -

In the demanding landscape of industrial fluid handling, maintaining seal integrity in high-temperature environments is a paramount challenge for engineers. As centrifugal pumps and valves operate und...

READ MORE -

In high-pressure and high-temperature industrial environments, achieving a hermetic seal is paramount for operational safety and environmental compliance. The corrugated graphite gasket has emerged as...

READ MORE

The Rising Star of Industrial Sealing: Exploring the Versatility of Metal-Jacketed Gaskets?

In a complex and ever-changing industrial environment, sealing technology is a key link to ensure the stable operation of equipment and prevent medium leakage. Its importance is self-evident. With the advancement of science and technology and the increasing diversification of industrial needs, traditional sealing materials can no longer meet the needs of all application scenarios. Against this background, Metal cladding gaskets came into being. With their unique structure and excellent performance, they have shown strong vitality in many industries such as shipping, electricity, steel, chemicals, machinery, etc., and have become an important part of modern industrial sealing technology.

Metal cladding gaskets are a composite sealing material that tightly combines metal sheets with soft inorganic high-heat-resistant sealing fillers. This unique structural design combines the strength, rigidity and corrosion resistance of metal materials with the flexibility and sealing of soft fillers, achieving complementary advantages and providing an ideal solution for sealing needs under various extreme working conditions. The inner layer is usually made of non-metallic materials such as flexible graphite, polytetrafluoroethylene, asbestos rubber sheet or ceramic fiber, which have good high temperature resistance, chemical corrosion resistance and good compression resilience; the outer layer is covered with a layer of metal sheet, such as stainless steel, aluminum, copper, etc., to enhance the overall strength, wear resistance and impact resistance of the gasket.

Excellent sealing performance: The inner soft filler can fit the sealing surface tightly and effectively fill the tiny gaps. Even under high temperature, high pressure or highly corrosive media, it can maintain a stable sealing effect.

Good adaptability: Metal-clad gaskets are suitable for various irregular or complex flange sealing surfaces. Through cold processing and forming technology, they can accurately match various sealing requirements.

High strength and corrosion resistance: The addition of the outer metal sheet significantly improves the overall strength and corrosion resistance of the gasket, extends its service life and reduces maintenance costs.

Wide range of applications: From low temperature to high temperature (up to hundreds of degrees Celsius), from low pressure to high pressure (including ultra-high pressure environment), metal-clad gaskets can perform well and meet the sealing requirements under different working conditions.

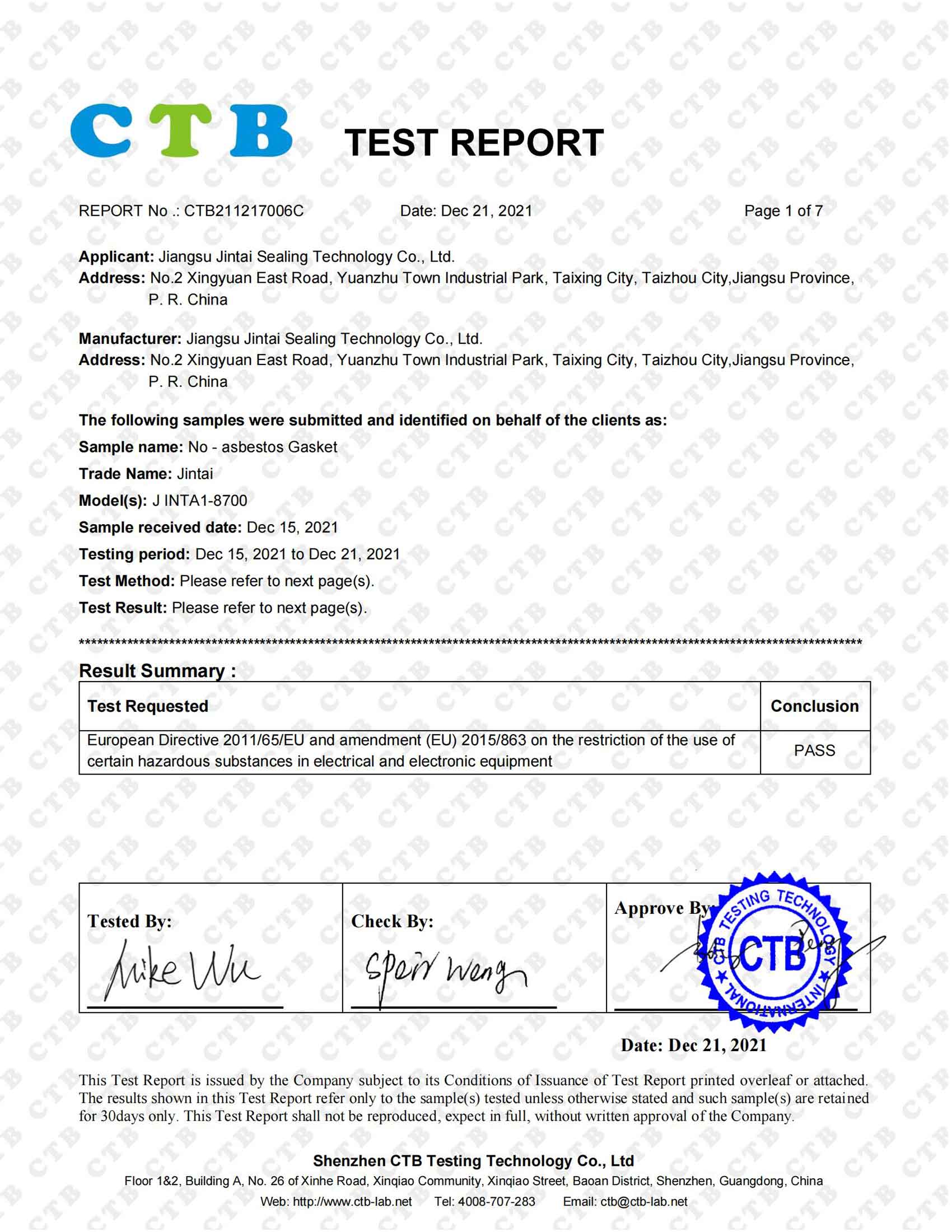

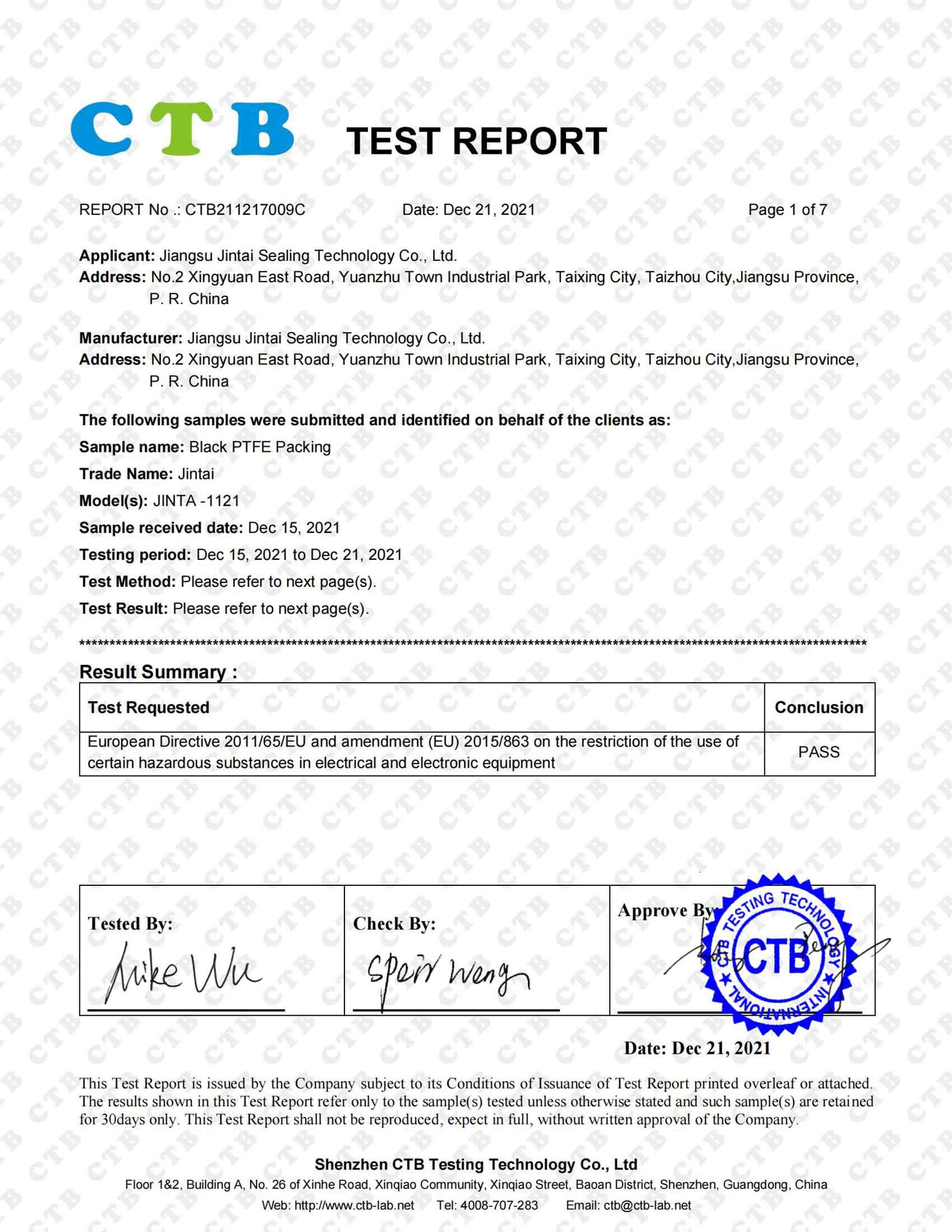

Environmentally friendly: With the improvement of environmental awareness, many metal-clad gaskets use asbestos-free materials as the inner layer, which meets the requirements of modern industry for environmentally friendly products.

In the shipbuilding industry, metal-clad gaskets are widely used in the sealing of hull pipes, valves and pumps, effectively preventing the leakage of media such as seawater and fuel oil, and ensuring navigation safety. In the power industry, the sealing of key equipment such as high-temperature and high-pressure boilers and steam turbines is also inseparable from the support of metal-clad gaskets. In the steel, chemical and machinery manufacturing industries, facing the complex and changing media environment, metal-clad gaskets have become indispensable sealing elements with their excellent sealing performance and corrosion resistance.

With the advancement of Industry 4.0 and intelligent manufacturing, the requirements for sealing technology will become more stringent and diversified. As a representative of advanced sealing materials, the research and development and application of metal-clad gaskets will continue to deepen, and develop towards higher performance, wider scope of application, and more convenient installation and maintenance. For example, improving the performance of the inner layer filler through nanotechnology, or using smart materials to achieve real-time monitoring and self-adjustment of the gasket status will bring new development opportunities for metal-clad gaskets.

As an important innovative achievement in the field of industrial sealing, metal-clad gaskets provide efficient and reliable sealing solutions for multiple industries with their unique structure and excellent performance. With the continuous advancement of technology and the continuous expansion of applications, metal-clad gaskets will play a more important role in ensuring industrial production safety, improving equipment operation efficiency, promoting energy conservation and emission reduction, and become an important force in promoting industrial transformation and upgrading. Industry leaders such as Jiangsu Jintai Sealing Technology Co., Ltd. are leading the metal-clad gasket industry to a higher level through continuous technology research and development and market expansion.

Eng

Eng  русский

русский