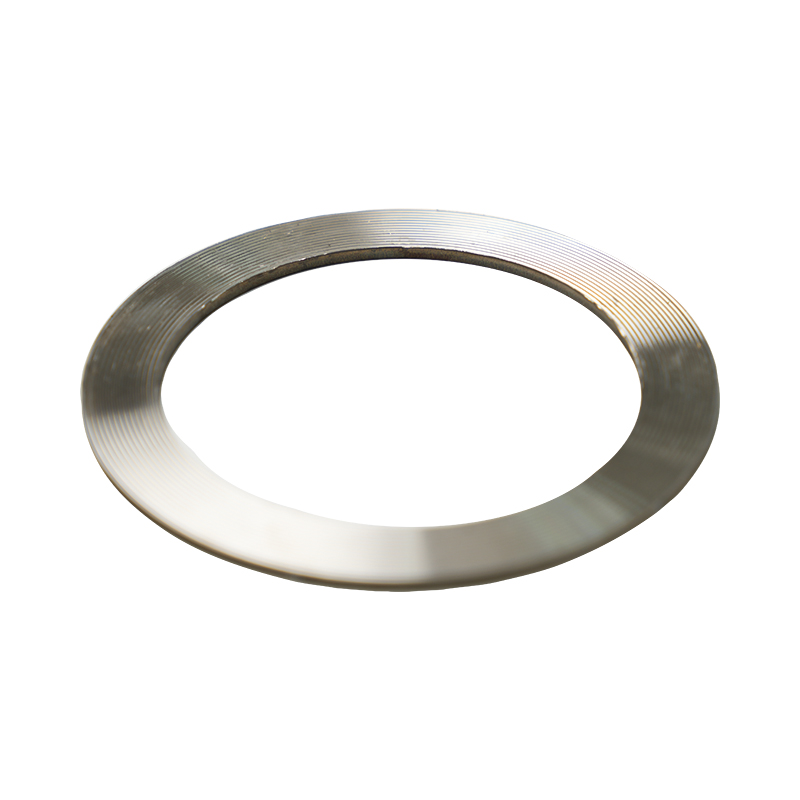

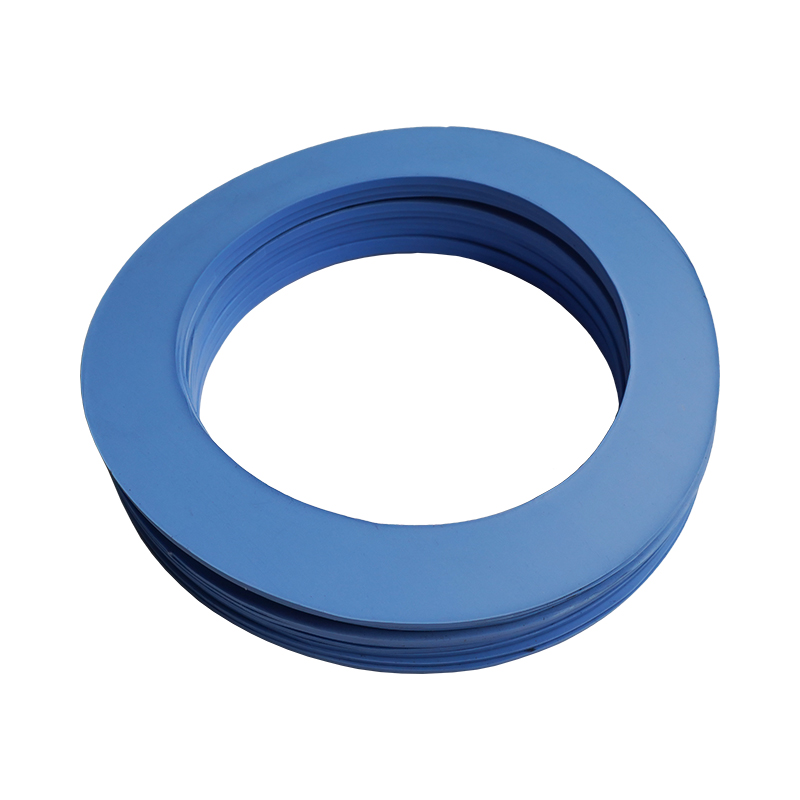

304ss/316ss Corrugated Metal Graphite Gasket

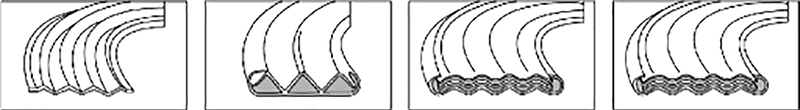

Corrugated metal gaskets are made of thin metal plates and pressed into concentric rings. They can also be made by bonding. They are basically line contact gaskets. The corrugations provide mechanical support. Their resilience depends on the form used and the thickness of the metal. Determined by corrugation spacing and corrugation height.

| Material | 304 Stainless Steel / 316 Stainless Steel, Graphite |

| Temperature Range | Graphite: Typically from -200°C to +900°C |

| Pressure Range | Maximum working pressure typically 100 MPa (depending on actual design and thickness) |

| Sealing Pressure | Suitable for high-pressure sealing, generally from 4 to 50 MPa |

| Compressibility | Typically 5% - 30% (depending on the combination of corrugated metal and graphite) |

| Thickness | Corrugated metal layer thickness typically 0.2-1.5mm, graphite layer can be customized as needed |

| Size Range | Customizable according to customer requirements, generally suitable for standard flange sizes (ANSI, DIN, etc.) |

| Corrosion Resistance | Good chemical corrosion resistance, with 316SS providing superior resistance in aggressive environments |

| Applicable Media | Water, oil, gas, acids, alkalis, and other chemicals, suitable for harsh working environments |

| Common Applications | Boilers, pressure vessels, heat exchangers, steam pipelines, etc. |

304SS/316SS Corrugated Metal Graphite Gasket For Sealing Gaskets With High Temperature, High Pressure And Corrosive Media

Our 304SS/316SS Corrugated Metal Graphite Gasket is a high-performance metal corrugated gasket designed to provide reliable sealing under extreme working conditions. This product uses stainless steel (304SS or 316SS) as the metal skeleton and is covered with a flexible graphite sealing layer on both sides. It has excellent compression resilience and sealing performance and is suitable for a variety of industrial applications, including boilers, pressure vessels, heat exchangers, steam pipes, etc.

Key Features:

Material Options: 304SS (standard corrosion resistance) / 316SS (enhanced chemical resistance)

Construction: Corrugated metal core with flexible graphite filler

Temperature Range: -200°C to +650°C (-328°F to +1202°F)

Pressure Rating: Up to 3000 psi (depending on application)

Standards Compliance: ASME B16.20, API 6A, EN 1514

Why Choose Our Gasket?

① Superior High-Temperature Performance

Our 304SS corrugated metal graphite gasket for high temperature maintains a tight seal even under extreme thermal cycling, making it perfect for boilers, exhaust systems, and refinery applications.

② Excellent Chemical Resistance

The 316SS corrugated graphite gasket chemical resistance makes it ideal for handling acids, alkalis, and corrosive media in chemical processing, petrochemical, and marine industries.

③Ideal for Piping Systems

Recognized as the best corrugated metal gasket for piping systems, it ensures leak-free connections in oil & gas, water treatment, and power plants.

④ Reliable Flange Sealing

Engineered for 304SS/316SS corrugated metal graphite gasket for flange sealing, it prevents leaks in high-pressure flange joints, reducing maintenance downtime.

⑤ Low Bolt Load Requirement

Unlike traditional gaskets, our 304SS/316SS corrugated gasket with low bolt load requirement minimizes flange stress while maintaining a secure seal, extending equipment lifespan.

⑥ Perfect for Heat Exchangers & Corrosive Media

The 304SS/316SS corrugated metal gasket for heat exchanger and corrosive media applications ensures long-term durability even in aggressive environments.

Applications (Where Is It Used?)

✔ Oil & Gas – Pipeline flanges, compressors, wellheads

✔Chemical Processing – Reactors, pumps, acid storage

✔ Power Generation – Steam turbines, heat exchangers

✔ Marine & Shipbuilding – Seawater-resistant sealing

✔ HVAC & Refrigeration – High-pressure refrigerant lines

Why Customers Choose Us?

Longer Lifespan – Resists creep relaxation, reducing replacement frequency.

Wide Compatibility – Works with ANSI, DIN, and JIS flanges.

Custom Sizes – Available in standard & non-standard dimensions.

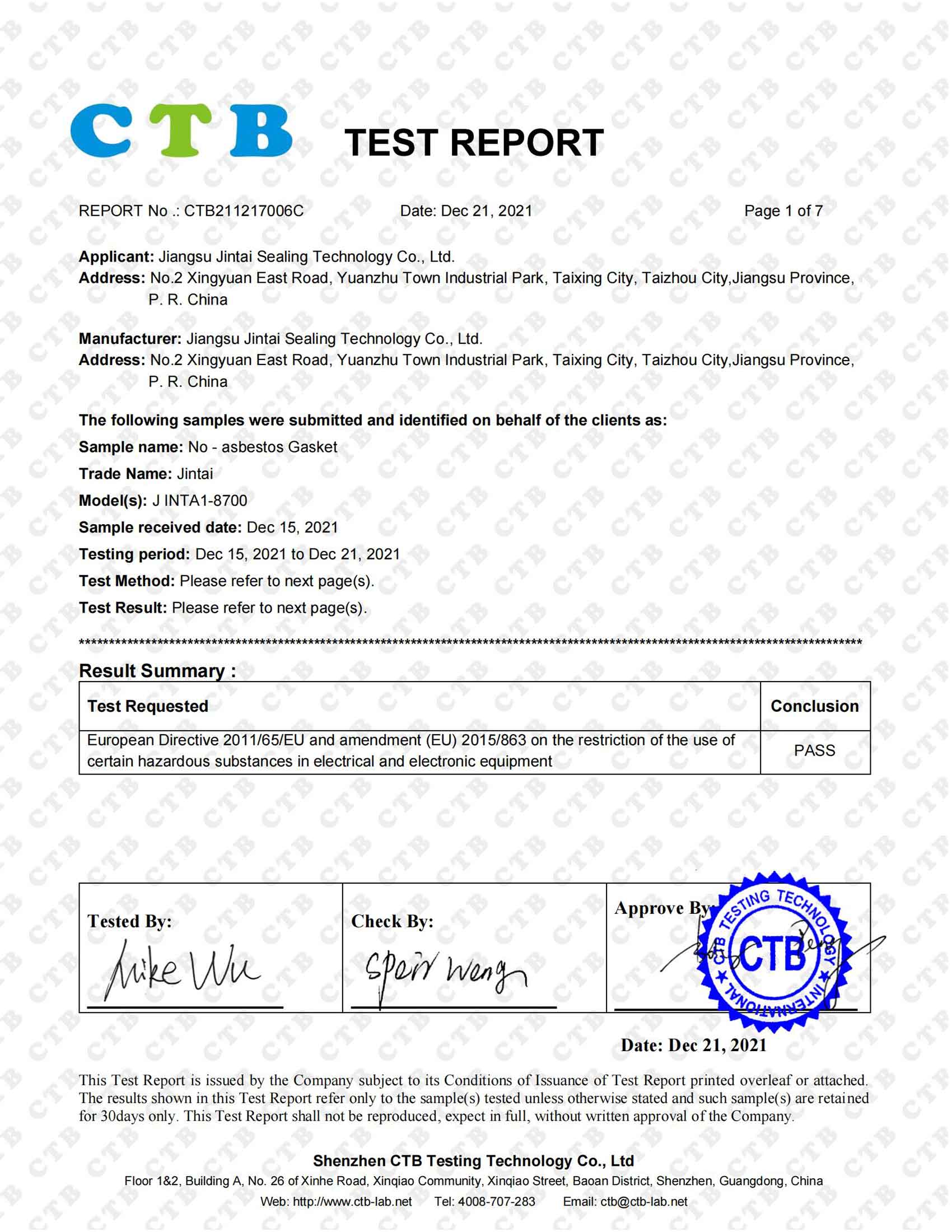

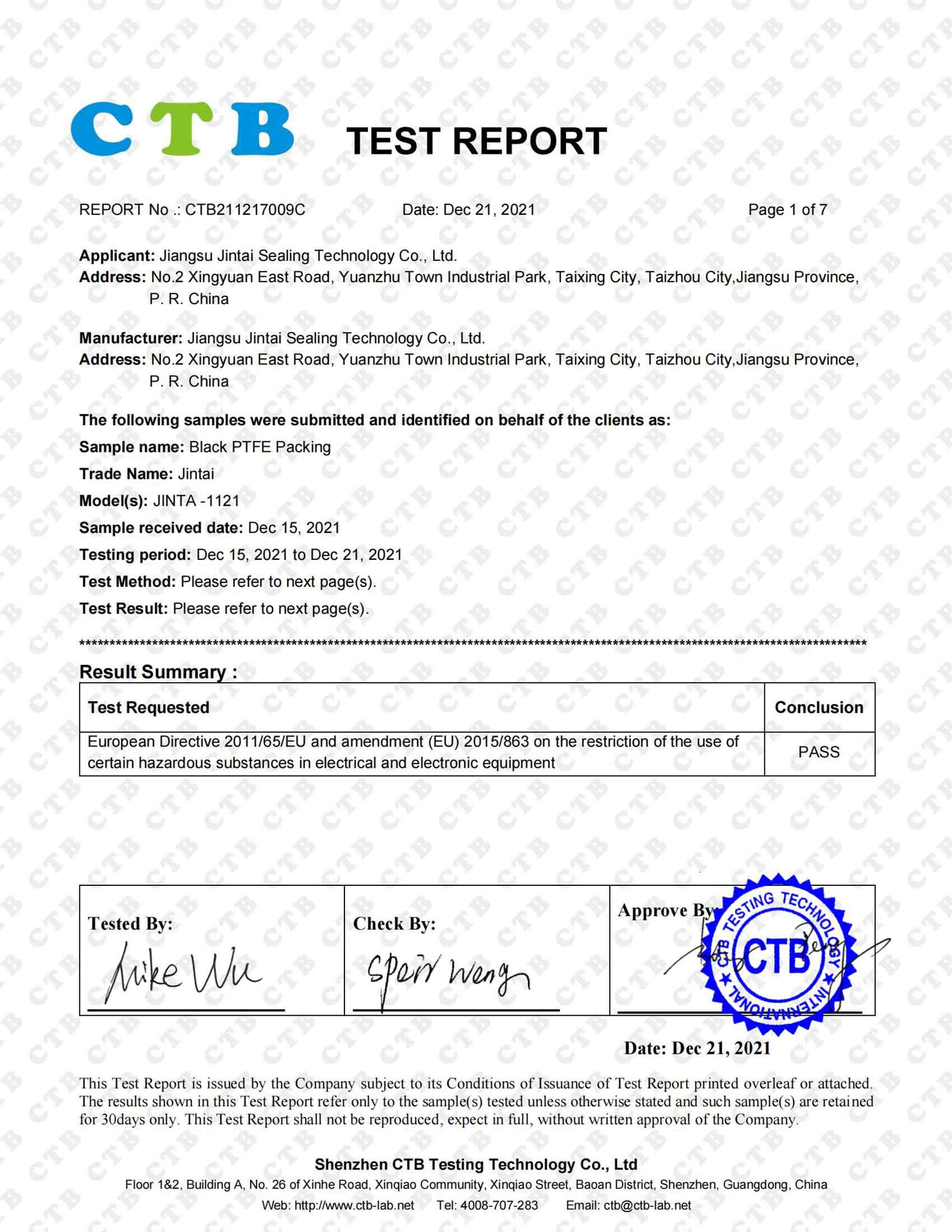

Certified Quality – ISO 9001, PED, and TA-Luft compliant.

Specifications

KEEP IN TOUCH

-

I. Introduction: The Technical Parameters of Sealing In the highly demanding environments of modern industrial machinery—across the power generation, chemical processing, and shipping sectors—the func...

READ MORE -

I. Sealing Solutions for Extreme Industrial Environments In critical industrial applications—spanning shipping, power generation, iron and steel, and chemistry—the integrity of dynamic seals is paramo...

READ MORE -

In critical industrial applications—from power generation to petrochemical processing—the performance of pure graphite gland packing is measured by its ability to reliably contain media across extreme...

READ MORE

How can the high temperature and corrosion resistant metal corrugated gasket not win wide acclaim in the market?

In the vast industrial field, sealing technology is a key link to ensure the safe and stable operation of equipment, and its importance is self-evident. In this field, Jiangsu Jintai Sealing Technology Co., Ltd. has become a leader in the industry with its outstanding innovation ability, exquisite manufacturing technology and extensive application practice. In particular, the metal corrugated gaskets produced by the company have won wide acclaim in the market for their unique performance and wide application scenarios.

Jiangsu Jintai Sealing Technology Co., Ltd. is located in the scenic Xingyuan Road, Yuanzhu Industrial Park, Taixing City, Jiangsu Province. Since its establishment in 2004, it has been committed to the research and development and innovation of sealing technology. Years of intensive cultivation have not only accumulated profound industry experience for Jintai Sealing, but also forged its strong technical strength and production capacity. The company has a complete quality management manual and monitoring system to ensure that every product can meet the highest industry standards and meet the stringent requirements of customers.

As one of the star products of Jintai Sealing Technology Company, the uniqueness of metal corrugated gaskets lies in their excellent sealing performance and wide applicability. The gasket is made of high-quality metal materials and has a unique corrugated structure after precision processing. This structure can not only effectively increase the elasticity of the gasket, but also automatically adjust its shape when under pressure to ensure the close fit of the sealing surface, thereby achieving excellent sealing effect.

Metal corrugated gaskets also have good high temperature resistance, corrosion resistance, wear resistance and other characteristics, and can operate stably for a long time in harsh working environments. These excellent properties have made metal corrugated gaskets widely used in many industries such as shipping, electricity, steel, chemical industry, machinery, etc., and have become an important tool for ensuring equipment safety and improving production efficiency.

In the R&D team of Jintai Sealing Technology Company, a large number of top experts and technical talents in the industry are gathered. They keep pace with the times, constantly explore the application of new technologies, new processes and new materials, and are committed to promoting the continuous progress and innovative development of sealing technology. It is precisely with such a dynamic and creative team that Jintai Sealing can always maintain its leading position in the fierce market competition and continuously launch high-quality products with independent intellectual property rights.

Jintai Sealing also spares no effort in the research and development and innovation of metal corrugated gaskets. The company not only continues to optimize the design structure and production process of its products, but also actively explores new application areas and market demands, and strives to provide customers with more comprehensive and personalized solutions. This customer-centric and market-oriented innovation concept is the key to Jintai Sealing's ability to win wide recognition and trust in the market.

In the future, Jiangsu Jintai Sealing Technology Co., Ltd. will continue to uphold the business philosophy of "quality first, customer first", and devote itself to the research and development and innovation of sealing technology with greater enthusiasm and firmer confidence. I believe that in the near future, Jintai Sealing will launch more excellent products like metal corrugated gaskets, and contribute more to promoting the industrial development of my country and even the world.

Eng

Eng  русский

русский