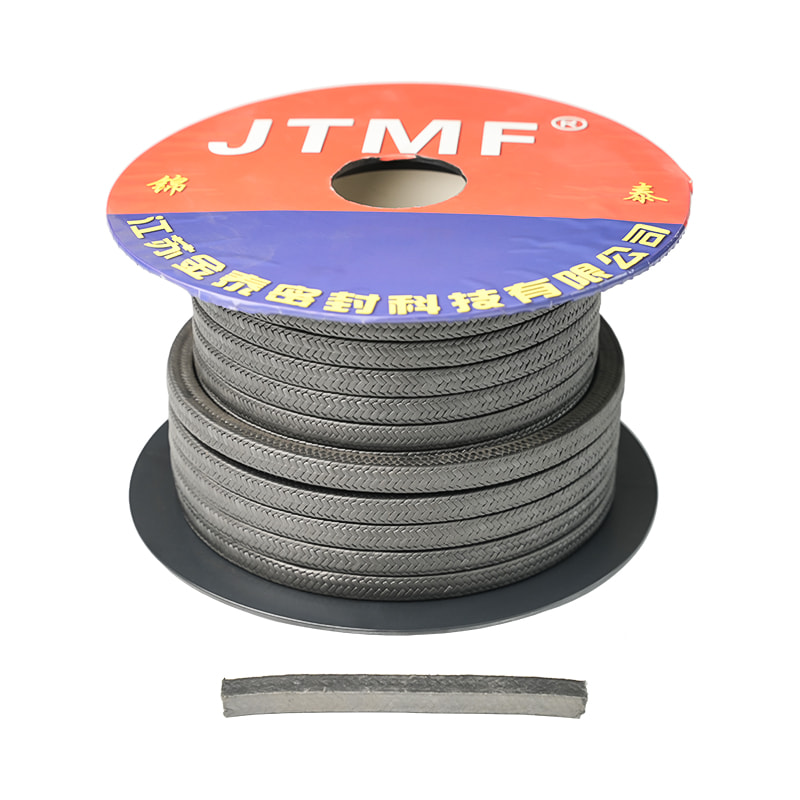

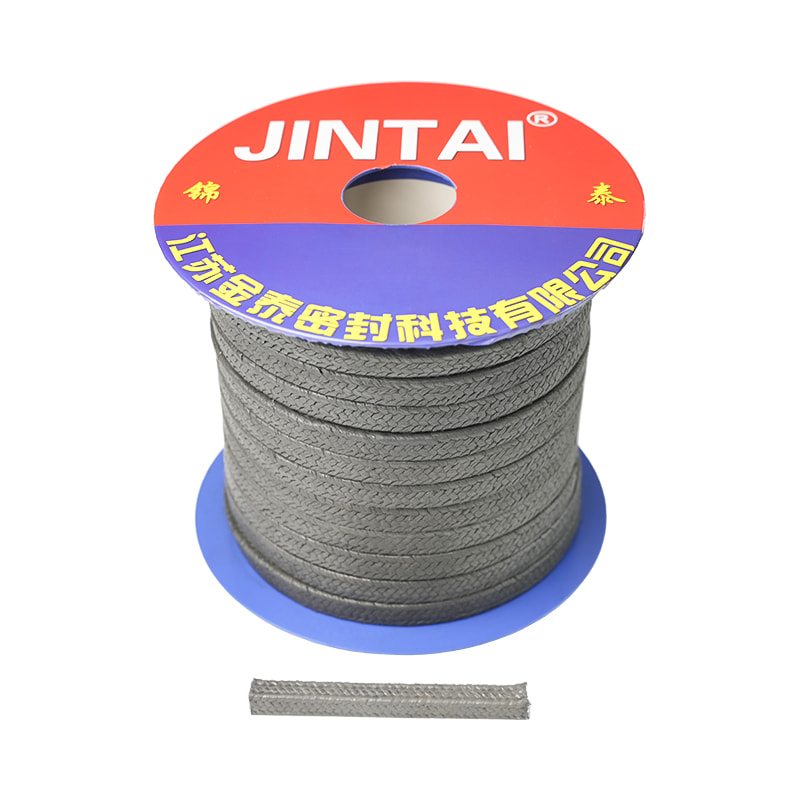

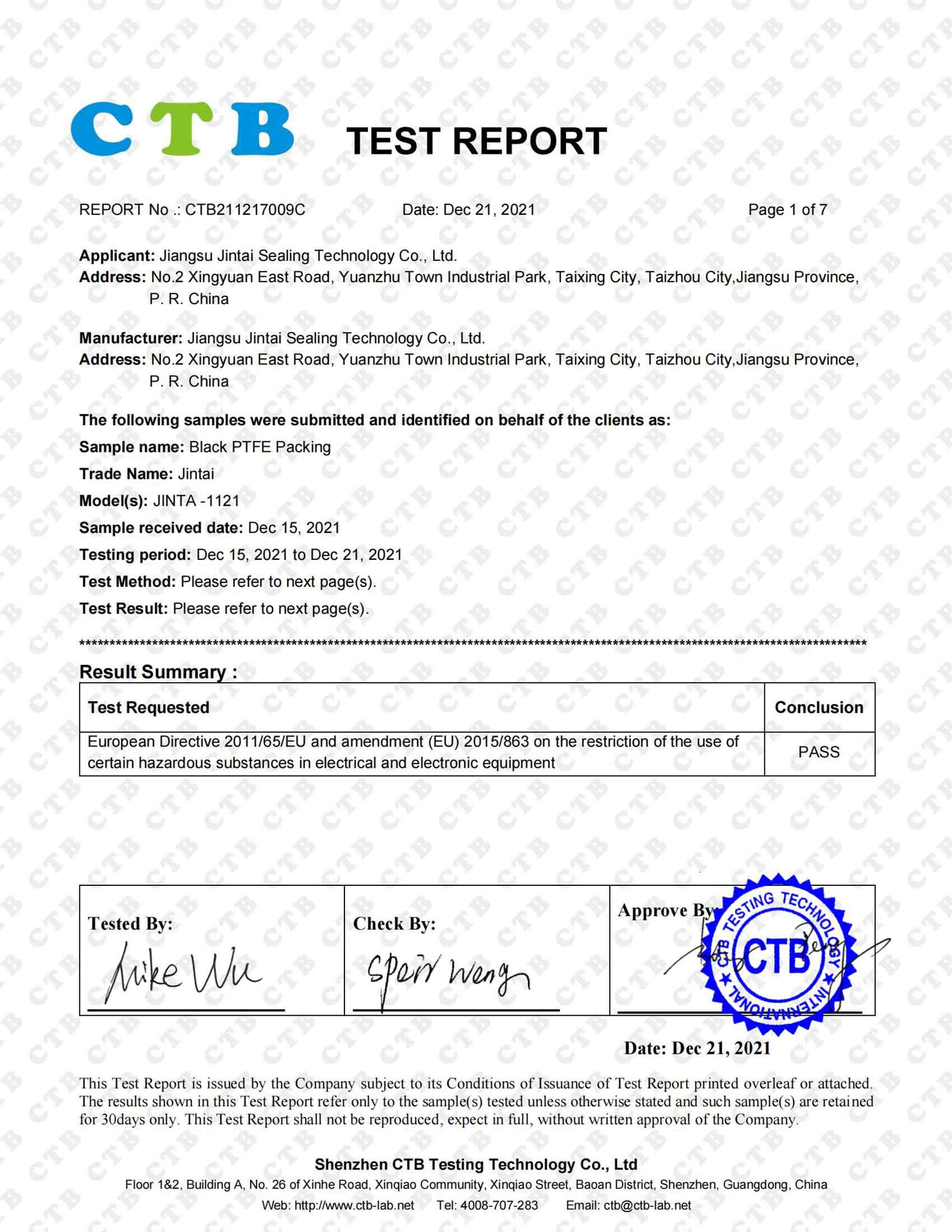

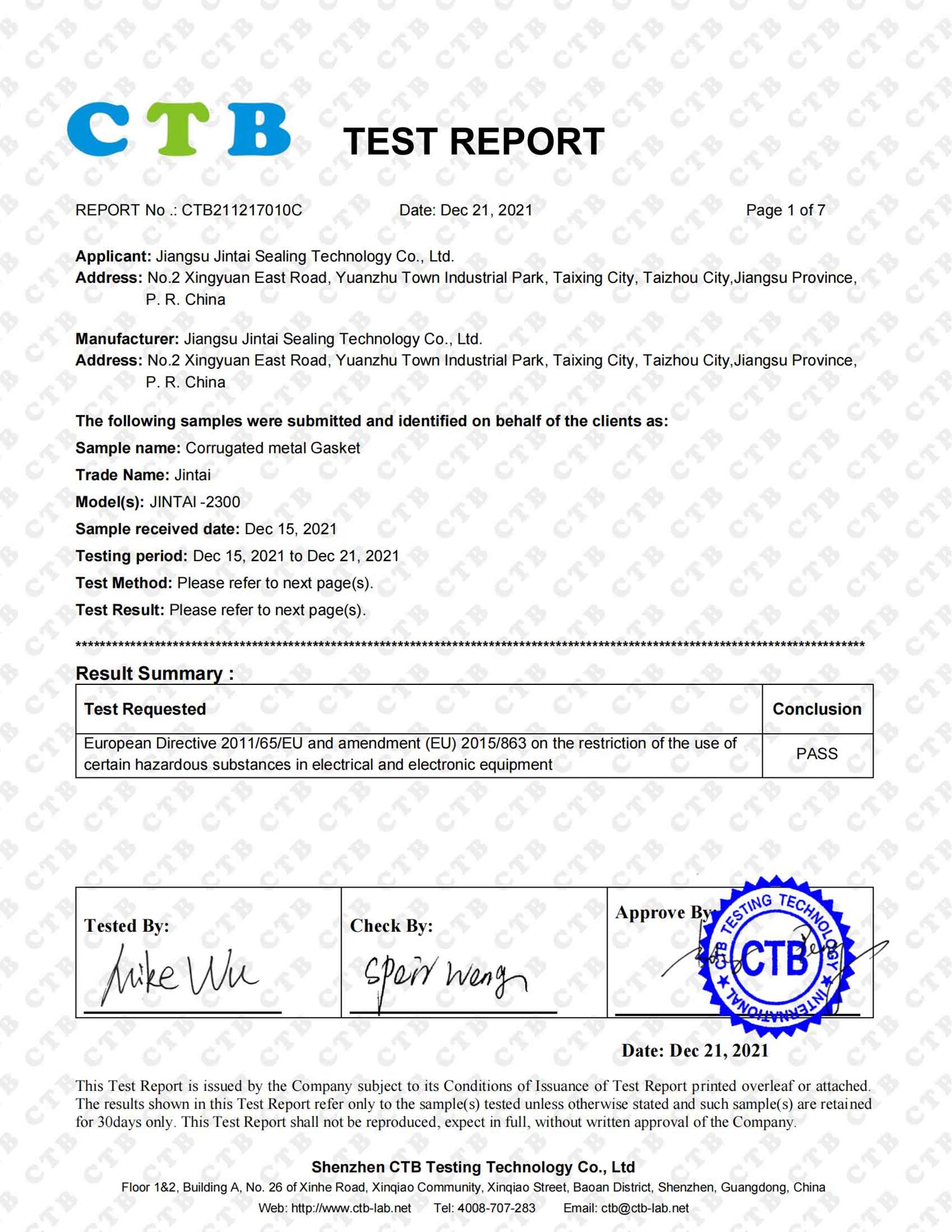

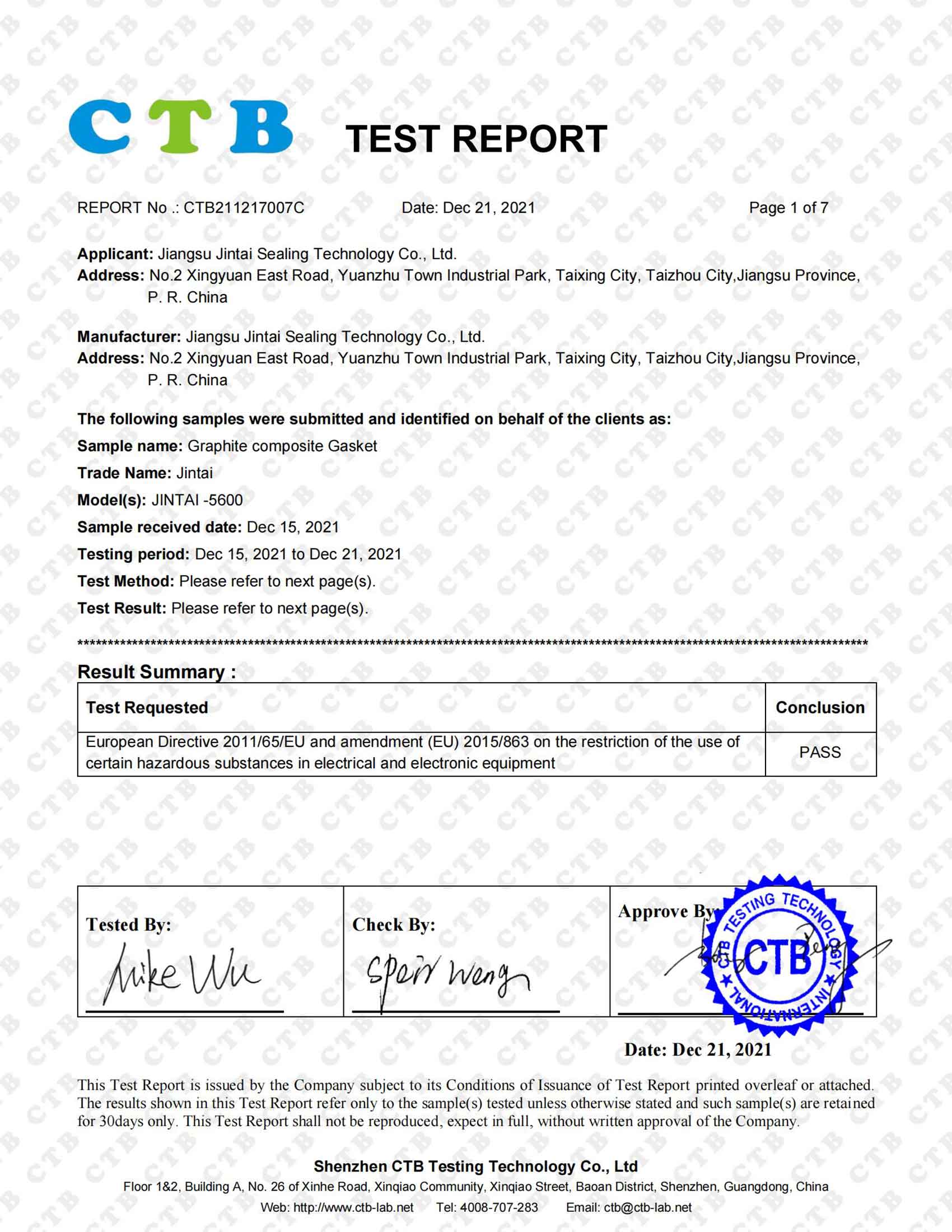

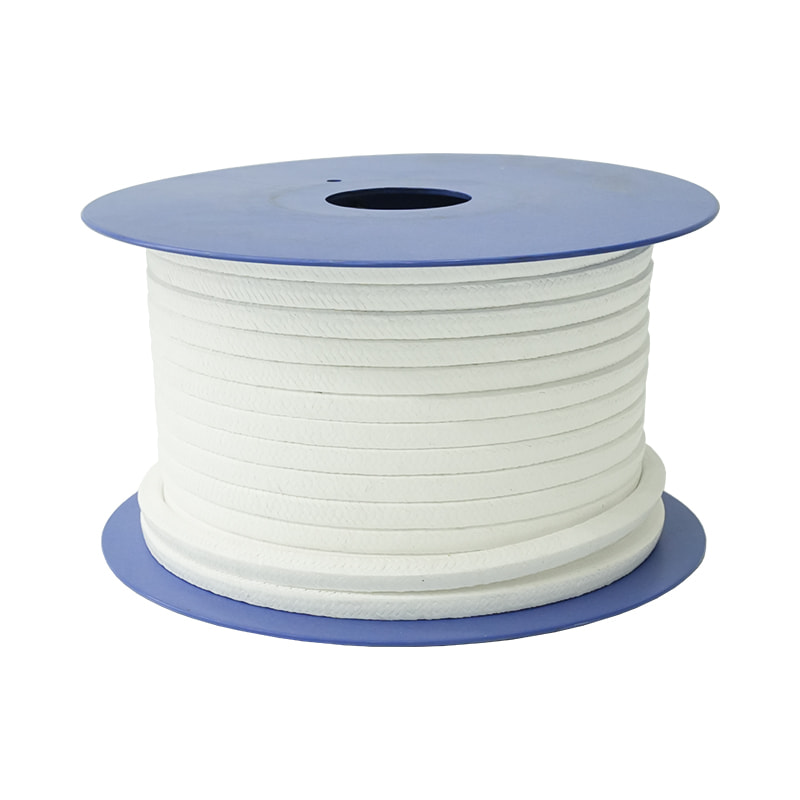

Valves Pump Gland Packing Seals White Pure PTFE Gland Packing

Reinforced PTFE packing uses high-strength inorganic fibers to make up for the lack of strength of the raw polytetrafluoroethylene film, overcomes the cold flow properties of pure polytetrafluoroethylene products, and also improves the wear resistance. It can be widely used in valves and rotary pumps with anti-fouling requirements, weak alkali, and strong acidic fluids.

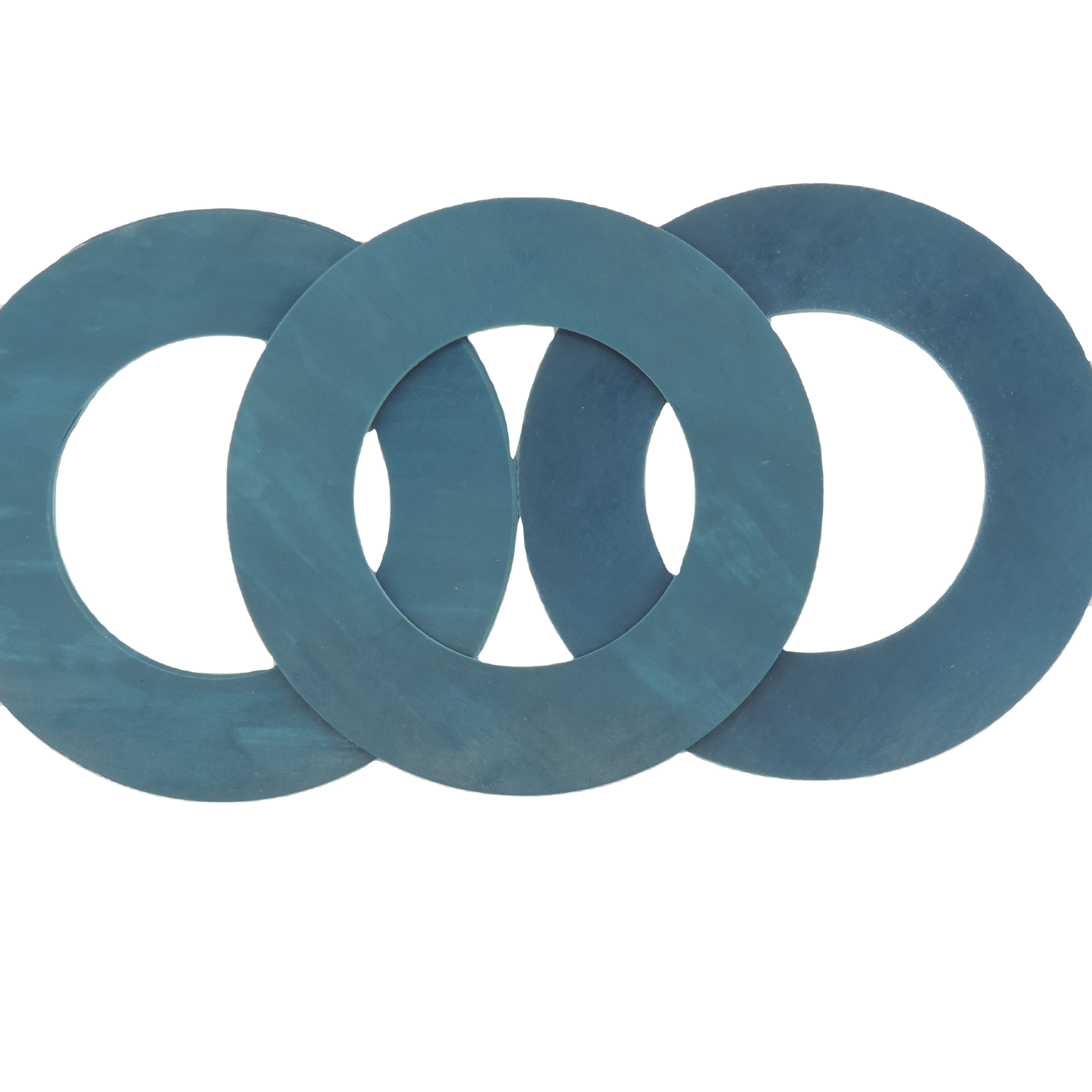

Valves Pump Gland Packing Seals White Pure PTFE Gland Packing is a high-performance sealing material designed for demanding industrial applications. Made of pure polytetrafluoroethylene (PTFE), it is chemically resistant and has a low friction coefficient, ensuring reliable sealing performance under extreme conditions. With strong temperature resistance and anti-aging properties, the packing is very suitable for pumps, valves and other rotating equipment, and is widely used in chemical, petrochemical, pharmaceutical and other industries. White Pure PTFE Gland Packing does not contain additives such as grease and graphite, ensuring safety in clean environments, while reducing equipment wear and extending service life. Easy to install and maintain, it can effectively reduce downtime and improve production efficiency.

Valves Pump Gland Packing Seals White Pure PTFE Gland Packing - Reliable Sealing Solution for Industrial Pumps and Valves

Product Features

- Material Composition: Constructed from pure PTFE to provide chemical resistance and low friction performance for valves and pumps.

- Temperature and Pressure Tolerance: Engineered to operate within a wide temperature range of -200°C to 260°C and withstand moderate to high pressure environments.

- Leakage Prevention: Designed for effective sealing in dynamic and static applications, minimizing operational fluid leakage and maintaining system efficiency.

Product Description

This PTFE gland packing is designed to provide consistent sealing performance in pumps, valves, and agitators. It functions by compressing around the pump shaft or valve stem to reduce leakage, ensuring operational reliability in chemical, petrochemical, and industrial processing applications.

Manufactured according to international standards, the product exhibits uniform density and precise dimensions, enhancing compatibility with various valve and pump designs. The chemical inertness of PTFE allows for use in corrosive environments, while the low friction coefficient minimizes wear and reduces torque requirements.

Applications

This gland packing seal is suitable for the following industrial scenarios:

- Chemical processing pumps requiring corrosion-resistant shaft sealing

- Petrochemical valves operating under high temperature and moderate pressure

- Agitators and mixers in food, pharmaceutical, and specialty chemical manufacturing

FAQ

1. What types of fluids can this PTFE gland packing handle?

This packing is compatible with a wide range of chemical fluids including acids, alkalis, solvents, and hydrocarbons, due to the chemical inertness of pure PTFE. It is suitable for both aqueous and non-aqueous media in industrial applications.

2. How is the gland packing installed in pumps and valves?

The packing is cut to fit the gland chamber, then compressed uniformly around the shaft or stem using gland bolts or packing followers. Proper installation ensures minimal leakage and reduces wear on rotating or reciprocating equipment.

3. What maintenance considerations are required for PTFE gland packing?

Periodic inspection of compression and wear is recommended. Unlike softer materials, PTFE maintains shape under load but may require adjustment of gland bolts over time. Replacement intervals depend on operating temperature, pressure, and fluid type.

Specifications

|

Temperature |

-40℃-+260℃ |

||

|

Pressure |

4Mpa(Rotary pump) |

10Mpa(Reciprocating pump) |

20Mpa(Valve) |

|

FH Value |

0-12 |

||

|

Line speed |

10M/S(Rotary pump) |

2M/S(Reciprocating pump) |

2M/S(Valve) |

|

Available cross-section sizes |

≥1/8''~≤3''(3×3-75×75mm) |

||

|

Density |

1.70-1.80g/cm³ |

||

|

Note: (1) The packing can be penetrated with high-temperature lubricant as needed. Density: 1.90-2.05g/cm³ (2) Iron red silicone strip elastomer can be added to the core of the packing as needed. |

|||

KEEP IN TOUCH

-

I. The Foundation of Reliable Sealing In high-stakes industrial environments—such as power generation, chemical processing, and shipping—the reliable containment of fluids is non-negotiable. Pure grap...

READ MORE -

I. Introduction: The Technical Parameters of Sealing In the highly demanding environments of modern industrial machinery—across the power generation, chemical processing, and shipping sectors—the func...

READ MORE -

I. Sealing Solutions for Extreme Industrial Environments In critical industrial applications—spanning shipping, power generation, iron and steel, and chemistry—the integrity of dynamic seals is paramo...

READ MORE

PTFE packing: the king of choice for industrial sealing, isn't it the solid backing of modern industry?

In the vast world of modern industry, sealing technology is a key link to ensure stable operation of equipment and improve production efficiency and safety. Its importance is self-evident. Polytetrafluoroethylene (PTFE), known as the "king of plastics", is unique in the field of sealing packing due to its excellent chemical stability, excellent high temperature resistance and extremely low friction coefficient, and has become the object of favor in many industries. Jiangsu Jintai Sealing Technology Co., Ltd., as a leader in this field, has pushed the application of polytetrafluoroethylene packing to a new height by relying on its profound industry background and technological innovation.

Polytetrafluoroethylene, as a polymer material that is inert to almost all chemical substances, can show extraordinary adaptability under extreme conditions. Its excellent corrosion resistance enables polytetrafluoroethylene packing to easily cope with the erosion of various media such as acids, alkalis, salts, solvents and even oxidants, and is widely used in harsh working environments such as ships, electricity, steel, and chemicals. The high-temperature stability of polytetrafluoroethylene is also extremely outstanding. It can maintain excellent physical and chemical properties in a wide temperature range of -200°C to +260°C, which is undoubtedly a great blessing for industrial equipment that needs to operate continuously at high temperatures.

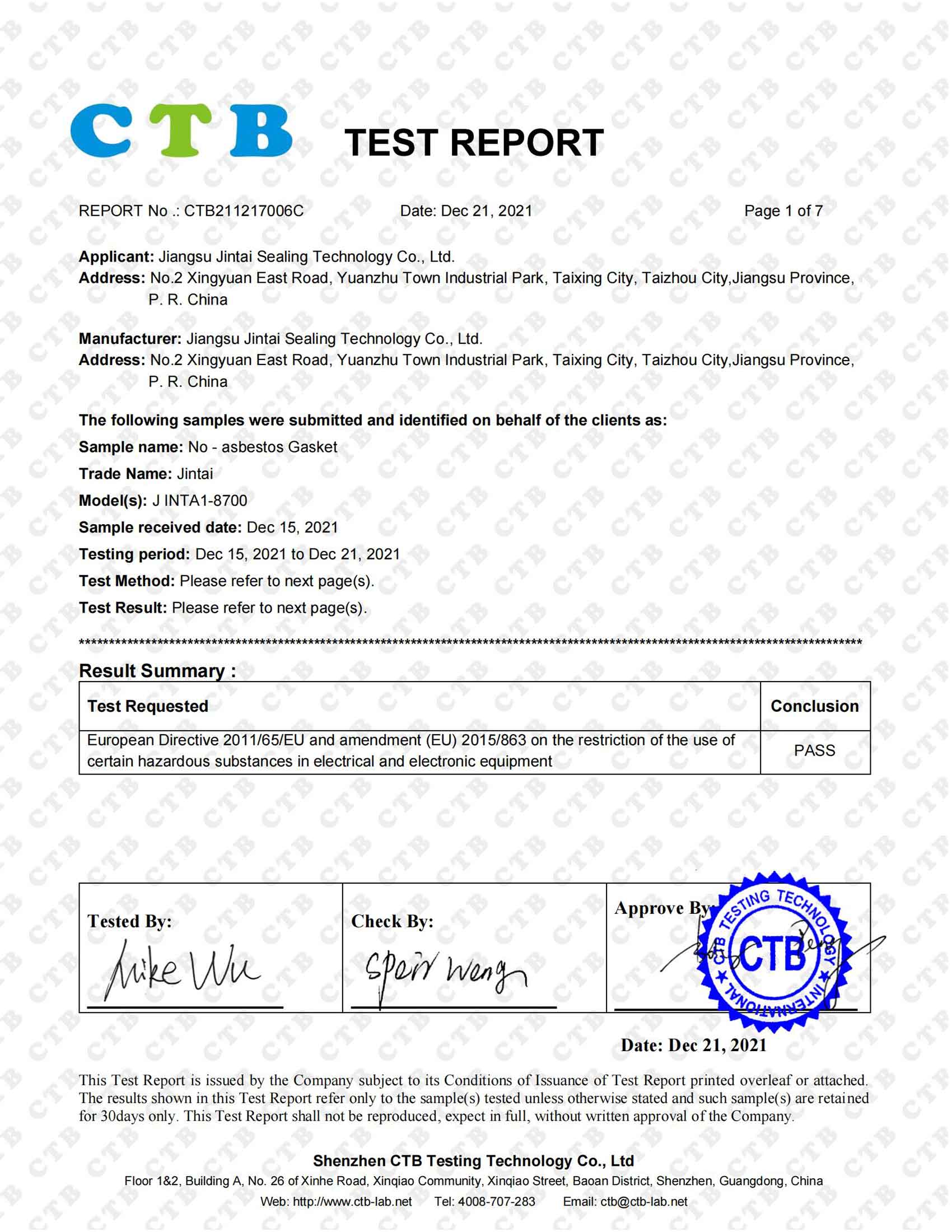

Since its establishment, Jiangsu Jintai Sealing Technology Co., Ltd. has always adhered to the business philosophy of "technological innovation, quality-oriented" and is committed to the research and development and production of high-end sealing products such as polytetrafluoroethylene packing. The company is located in the scenic Yuanzhu Industrial Park, Taixing City, Jiangsu Province. It has a modern production base and advanced production equipment to ensure that every product can meet the highest standards in the industry. Through years of scientific research and production accumulation, Jiangsu Jintai has not only established a complete quality management manual and monitoring system, but also has a research and development team composed of industry experts and technical backbones to continuously promote technological innovation and product upgrades.

Jiangsu Jintai's polytetrafluoroethylene packing has won wide recognition in many industries such as shipbuilding, power, steel, chemical industry, and machinery for its excellent performance and reliable quality. In the shipbuilding industry, polytetrafluoroethylene packing is used to seal key parts such as various valves and pump bodies, effectively preventing the leakage of seawater, oil and other media, and ensuring the safe navigation of ships; in the power industry, its excellent high temperature resistance makes polytetrafluoroethylene packing an ideal sealing material for high temperature equipment such as boilers and steam turbines; and in the chemical industry, facing various corrosive media, polytetrafluoroethylene packing has shown unparalleled stability, ensuring the continuity and safety of chemical production.

As an important part of modern industrial sealing technology, polytetrafluoroethylene packing is carefully built by Jiangsu Jintai Sealing Technology Co., Ltd., and is writing its own legendary chapter with its excellent performance and broad application prospects.

Eng

Eng  русский

русский