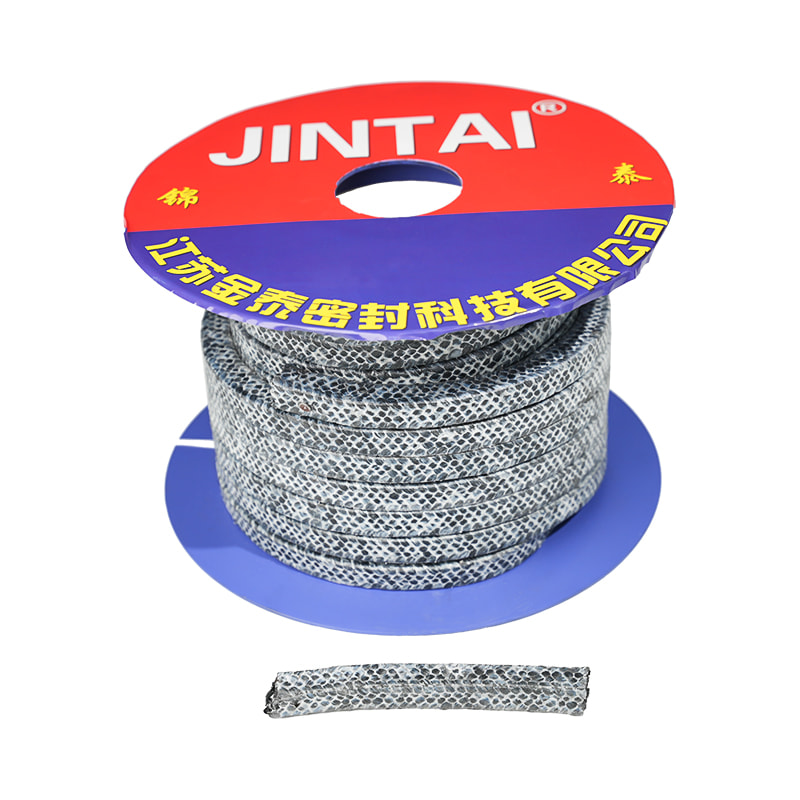

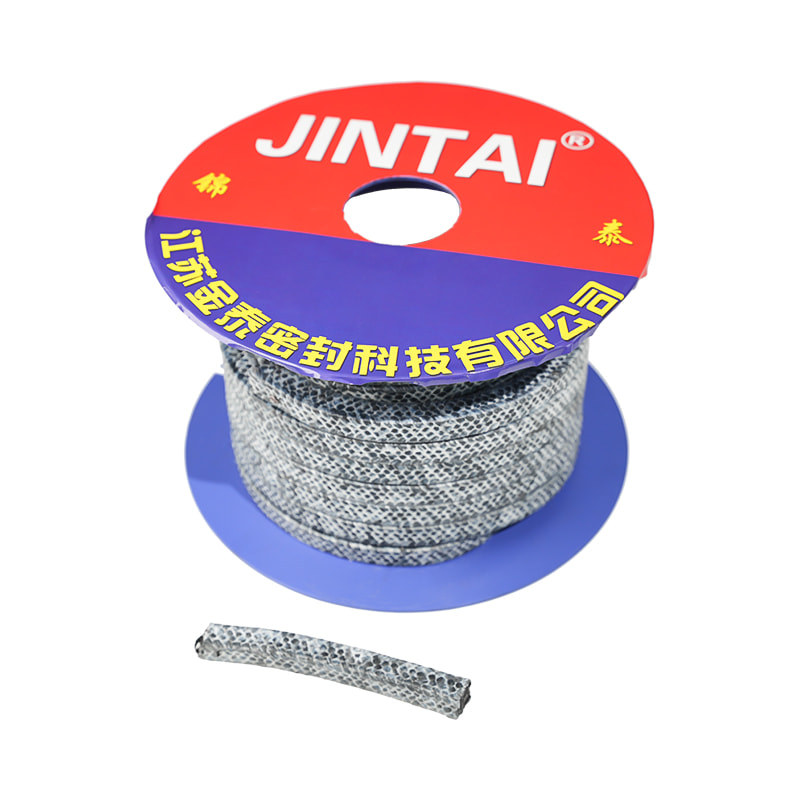

Fire Pump Valve Packing Glands Carbon Fiber Graphite Gland Packing

Carbon fiber graphite packing is made of high-strength, high-modulus continuous carbon fiber filaments, which are softened and then woven. This kind of packing is impregnated with a mixture of graphite powder, molybdenum disulfide, and polytetrafluoroethylene emulsion, and undergoes high-temperature curing treatment. It has better chemical stability and thermal conductivity, as well as high strength, and is especially suitable for chemical applications. The seals of various rotary pumps and reciprocating pumps that are highly corrosive and contain granular media, especially the high-pressure ammonium methane pump and liquid chlorine pump of the urea system, show that it is a promising high-temperature and high-pressure resistant, strong Filler for corrosive media.

Fire Pump Valve Packing Glands Carbon Fiber Graphite Gland Packing - Reliable Sealing for Industrial Fire Pump Systems

Product Features

- Material Composition: Constructed from carbon fiber and graphite to ensure thermal stability and chemical resistance under high-pressure conditions.

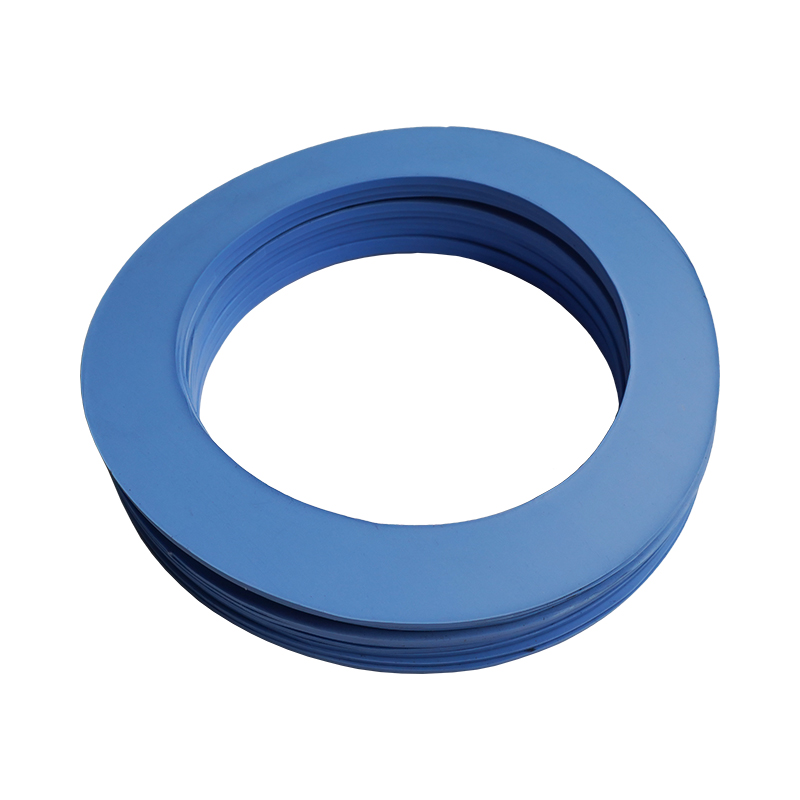

- Sealing Performance: Engineered to provide consistent sealing for fire pump valves, minimizing leakage and maintaining operational efficiency.

- Durability: Resistant to wear and friction, designed for extended service life in industrial fire protection systems.

Product Description

The carbon fiber graphite gland packing is designed for use in fire pump valve systems, providing reliable sealing under extreme operating conditions. Its structure combines high-strength carbon fibers with lubricating graphite, reducing friction while maintaining compression, suitable for high-pressure fire suppression applications.

Manufactured in accordance with international mechanical and fire safety standards, this gland packing meets ISO and API specifications. The precision-engineered dimensions ensure compatibility with standard fire pump valves, offering consistent sealing performance while minimizing maintenance frequency.

Application Areas

This gland packing is suitable for the following industrial scenarios:

- Fire pump valves in commercial and industrial fire suppression systems

- Pipelines and valves in high-temperature, high-pressure fluid transport

- Marine and offshore fire protection equipment requiring corrosion-resistant seals

FAQ

1. What types of fire pump valves are compatible with this carbon fiber graphite gland packing?

This gland packing is compatible with standard industrial fire pump valves, including inline, vertical, and horizontal configurations, conforming to API and ISO valve dimensions.

2. How does carbon fiber graphite composition improve sealing performance?

The carbon fibers provide structural strength and thermal stability, while the graphite offers lubrication and reduces friction. This combination ensures a tight seal, reduces wear on valve stems, and maintains operational reliability under high pressure and temperature.

3. What maintenance or replacement considerations should be followed?

Regular inspection of the packing for signs of wear, compression loss, or leakage is recommended. Replacement intervals depend on operating pressure, temperature, and valve cycling frequency. Proper installation torque and alignment are critical to maintaining performance.

Specifications

|

Temperature |

-200-+650℃(Steam) |

-200-+565℃(Atmosphere) |

|

|

Pressure |

5Mpa(Rotary pump) |

5Mpa(Reciprocating pump) |

25Mpa(Valve) |

|

PH Value |

0-14 |

||

|

Line speed |

20M/S(Rotary pump) |

2M/S(Reciprocating pump) |

2M/S(Valve) |

|

Available cross-section sizes |

≥1/8”~≤3"(3×3-75×75mm) |

||

|

Density |

1.35-1.45g/cm³ |

||

|

Note (1) The packing can be infiltrated with high-temperature lubricant as needed. Density: 1.60-1.70gcm³ (2) Iron red silicone strip elastomer can be added to the core of the packing as needed. |

|||

KEEP IN TOUCH

-

I. The Foundation of Reliable Sealing In high-stakes industrial environments—such as power generation, chemical processing, and shipping—the reliable containment of fluids is non-negotiable. Pure grap...

READ MORE -

I. Introduction: The Technical Parameters of Sealing In the highly demanding environments of modern industrial machinery—across the power generation, chemical processing, and shipping sectors—the func...

READ MORE -

I. Sealing Solutions for Extreme Industrial Environments In critical industrial applications—spanning shipping, power generation, iron and steel, and chemistry—the integrity of dynamic seals is paramo...

READ MORE

Carbon fiber graphite packing: the terminator of traditional sealing materials, isn't it a new chapter in industrial sealing?

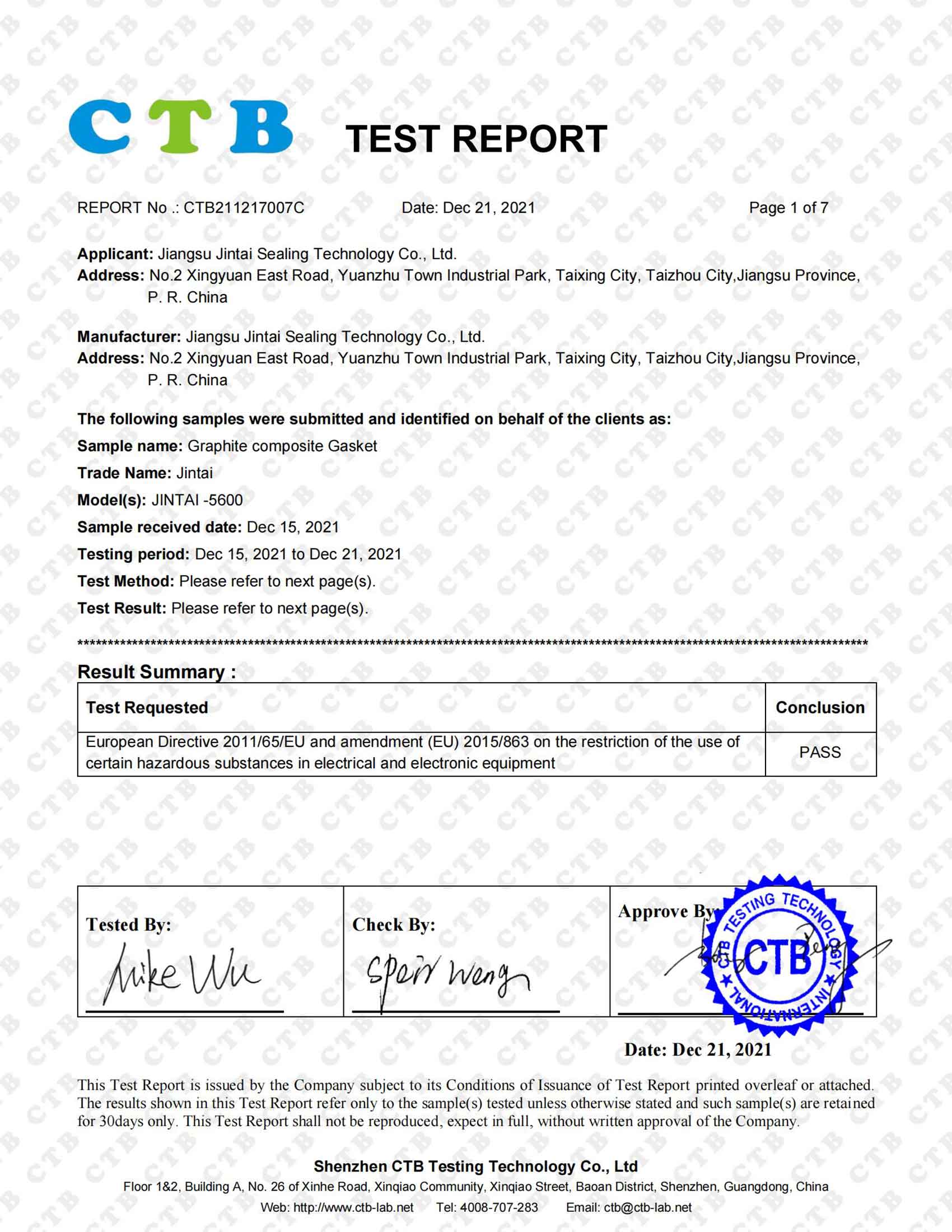

In the modern industrial field, with the continuous advancement of technology and the increasing complexity of equipment, the requirements for sealing materials have reached an unprecedented height. Especially under extreme working conditions such as high temperature, high pressure, and strong corrosion, traditional sealing materials are often difficult to cope with, and carbon fiber graphite filler, as a new type of high-performance sealing material, is gradually becoming the key to solving these problems. Jiangsu Jintai Sealing Technology Co., Ltd., with its profound scientific research strength and rich production experience, has successfully developed and launched carbon fiber graphite filler, bringing new breakthroughs in the field of industrial sealing.

Carbon fiber graphite filler is a new type of sealing material that combines carbon fiber and graphite materials through a special process. This material not only inherits the original excellent properties of graphite such as high temperature resistance, corrosion resistance, and self-lubrication, but also obtains higher strength, better thermal conductivity and lower thermal expansion coefficient due to the addition of carbon fiber. The perfect combination of these characteristics makes carbon fiber graphite filler reach a new height in sealing performance.

The addition of carbon fiber significantly improves the mechanical strength of the filler, enabling it to withstand greater pressure and torque, thereby ensuring the sealing stability under extreme working conditions. The combination of graphite's self-lubricating properties and carbon fiber's wear resistance effectively reduces the friction coefficient between the filler and the sealing surface, reduces energy consumption and wear, and extends the service life of the equipment. Carbon fiber graphite filler also has good thermal conductivity, which can quickly export the heat generated during the operation of the equipment to avoid sealing failure caused by local overheating.

The carbon fiber graphite filler produced by Jiangsu Jintai Sealing Technology Co., Ltd. has been widely used in many industries such as shipbuilding, electricity, steel, chemical industry, machinery, etc. due to its excellent performance and stable quality. In the field of ships, carbon fiber graphite filler is widely used in the sealing system of key equipment such as engines and pumps, effectively preventing the leakage of media such as seawater and fuel, and ensuring the safe navigation of ships. In the power industry, it helps the sealing of high-temperature and high-pressure equipment such as boilers and steam turbines, providing a strong guarantee for the continuity and stability of power production. In the chemical industry, facing various corrosive media such as strong acids and strong alkalis, carbon fiber graphite filler has demonstrated its extraordinary corrosion resistance, building a solid line of defense for the safe operation of chemical equipment.

As an innovative product of Jiangsu Jintai Sealing Technology Co., Ltd., carbon fiber graphite filler not only represents the company's latest achievements in the field of sealing technology, but also demonstrates the company's deep insight and grasp of future industrial sealing trends. With the continuous advancement of industrial technology and the increasing requirements for environmental protection, carbon fiber graphite filler will surely play its unique advantages in more fields and contribute more to the safe, efficient and environmentally friendly operation of industrial equipment. Jiangsu Jintai Sealing Technology Co., Ltd. will continue to uphold the development concept of "scientific and technological innovation, quality first", continuously promote the advancement of sealing technology and industrial upgrading, and contribute more wisdom and strength to promote the modernization of my country's industry.

Eng

Eng  русский

русский