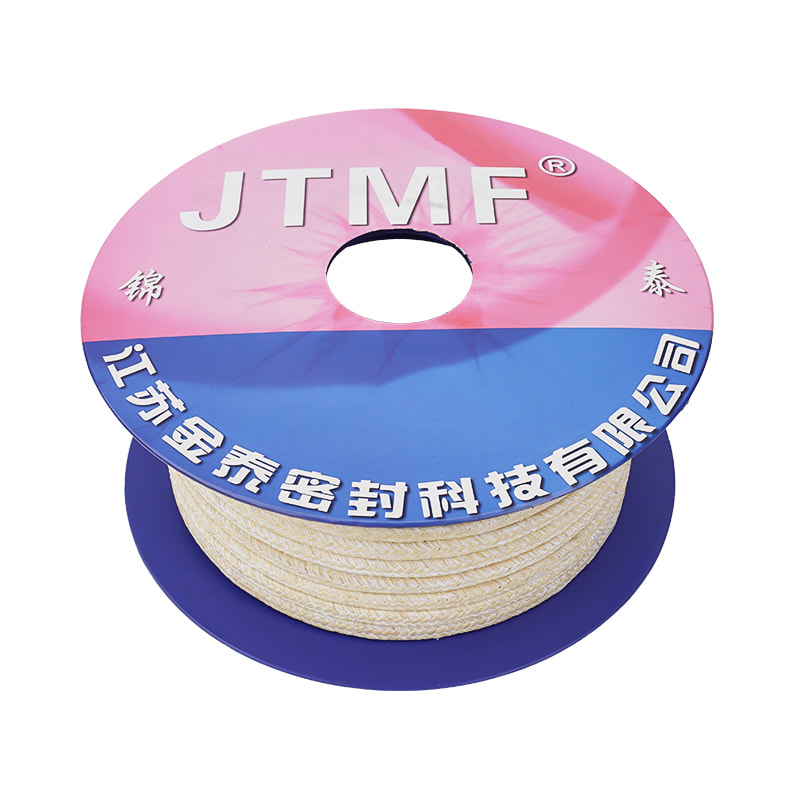

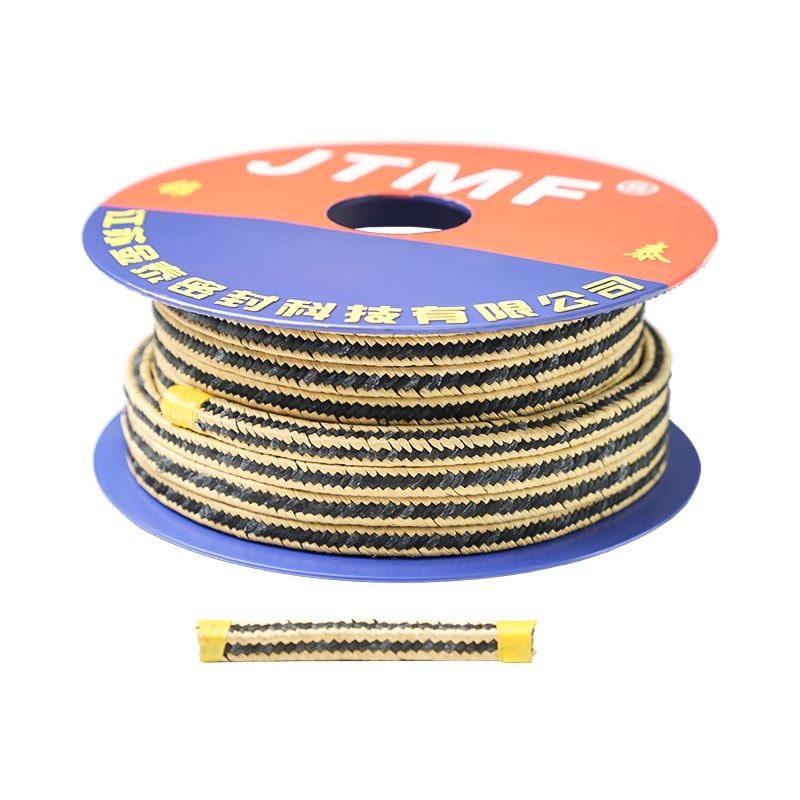

Cord Graphite Aramid Fiber Zebra Braided Gland Packing With Oil

Cord Graphite Aramid Fiber Zebra Braided Gland Packing with Oil is widely used in sealing systems of various industrial equipment. The product is made of high-strength aramid fiber (Aramid Fiber) and graphite (Graphite), and is processed through a unique braiding process to form a composite structure with wear resistance and corrosion resistance. The lubricating properties of graphite effectively reduce friction, while aramid fiber provides strength and high temperature resistance. The seal contains lubricating oil, which further improves the sealing effect and reduces friction and wear. This braided structure is suitable for shaft seals and sealing systems of equipment such as pumps, valves, and rotating equipment.

Cord Graphite Aramid Fiber Zebra Braided Gland Packing With Oil - Engineered for High-Temperature and Chemical-Resistant Sealing Applications

Product Features

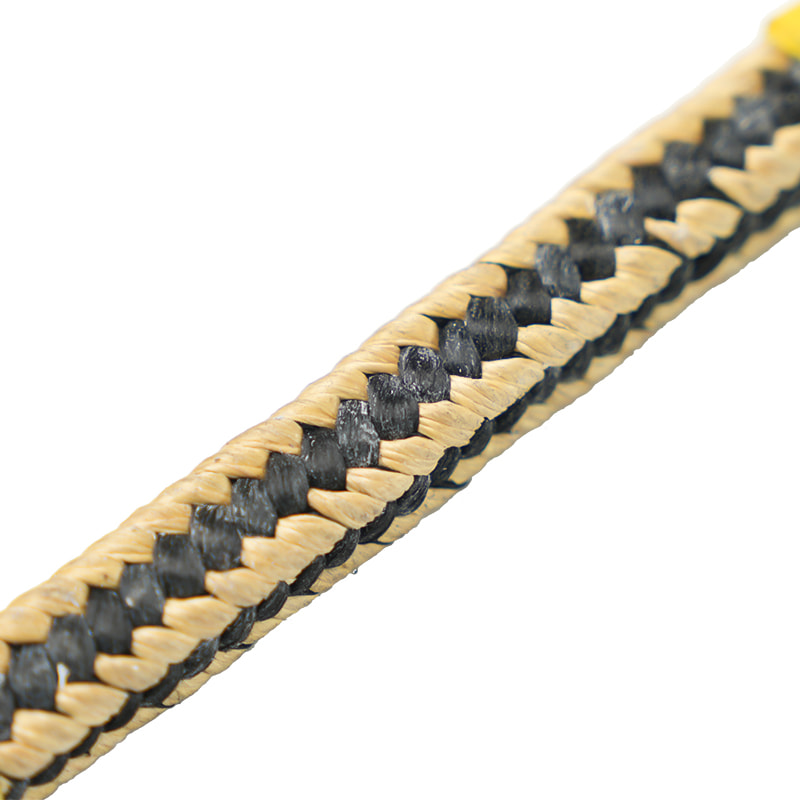

- Material Composition: Constructed from graphite-impregnated aramid fibers braided in a zebra pattern, providing stable structural integrity under mechanical stress.

- Temperature and Chemical Resistance: Capable of withstanding continuous temperatures up to 500°C and exposure to a wide range of industrial chemicals and lubricants.

- Enhanced Sealing Performance: Designed to reduce leakage in pumps, valves, and agitators by maintaining compression and resilience over extended operational cycles.

Product Description

The Cord Graphite Aramid Fiber Zebra Braided Gland Packing with Oil is engineered to meet the requirements of demanding industrial sealing applications. Its design combines high-strength aramid fibers with graphite impregnation, ensuring consistent performance in high-temperature and chemically aggressive environments.

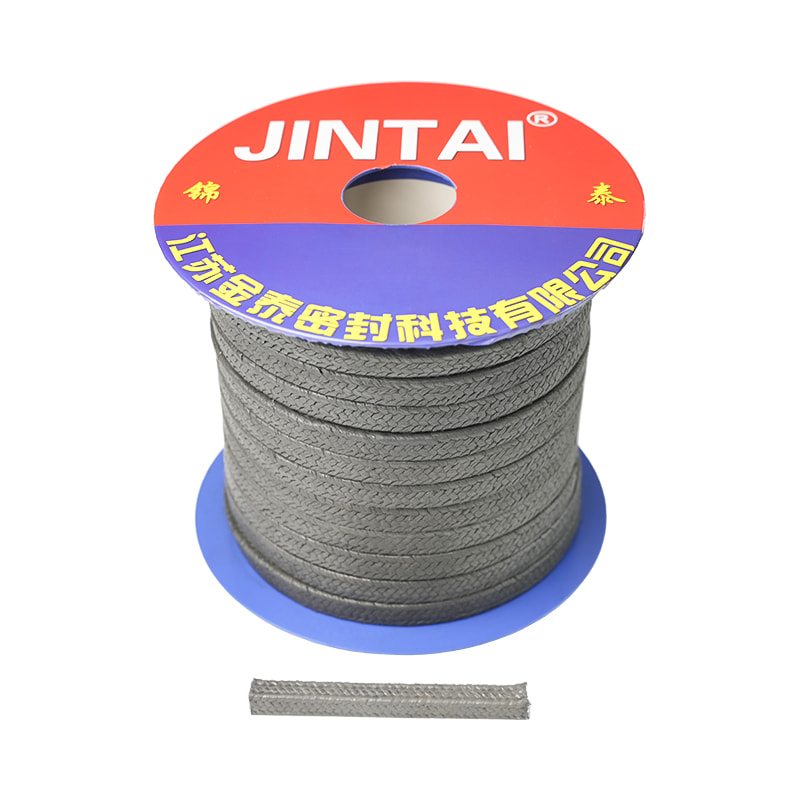

Manufactured according to international standards, the product demonstrates precise dimensional tolerances, uniform density, and controlled oil content. These characteristics ensure reliable sealing, minimal shaft wear, and extended maintenance intervals in pumps, mixers, and other rotating equipment.

Applications

This gland packing is suitable for various industrial settings that demand reliable sealing solutions:

- Pumps handling high-temperature fluids in chemical processing plants

- Valves in petroleum refining and petrochemical industries

- Mixers and agitators in pulp and paper manufacturing

- Rotating equipment in power generation and boiler systems

FAQ

1. What is the maximum operating temperature for this gland packing?

The packing can operate continuously at temperatures up to 500°C without degradation of mechanical properties or sealing performance.

2. Is this product compatible with aggressive chemicals?

Yes, the graphite-aramid construction provides resistance to a wide range of industrial chemicals, including oils, acids, and alkalis, making it suitable for chemical processing applications.

3. Can this packing be used in both rotary and reciprocating equipment?

Yes, the braided structure and oil impregnation allow stable performance in both rotary pumps and reciprocating valves, maintaining sealing integrity under dynamic operating conditions.

Specifications

|

Temperature |

-100℃-+260℃ |

||

|

Pressure |

50Mpa(Rotary pump) |

10Mpa(Reciprocating pump) |

20Mpa(Valve) |

|

PH Value |

2-12 |

||

|

Velvet Speed |

15M/S(Rotary pump) |

2M/S(Reciprocating pump) |

2M/S(Valve) |

|

Available cross-section sizes |

≥18''~≤3''(3×3-75×75mm) |

||

|

Density |

1.50-1.60g/cm³ |

||

|

Note: (1) Iron red silicone strip elastomer can be added to the core of the packing as needed. |

|||

KEEP IN TOUCH

-

I. The Foundation of Reliable Sealing In high-stakes industrial environments—such as power generation, chemical processing, and shipping—the reliable containment of fluids is non-negotiable. Pure grap...

READ MORE -

I. Introduction: The Technical Parameters of Sealing In the highly demanding environments of modern industrial machinery—across the power generation, chemical processing, and shipping sectors—the func...

READ MORE -

I. Sealing Solutions for Extreme Industrial Environments In critical industrial applications—spanning shipping, power generation, iron and steel, and chemistry—the integrity of dynamic seals is paramo...

READ MORE

Aramid packing: A new era of sealing technology, isn't it the guardian of industrial safety?

In the rapidly developing modern industrial system, sealing technology is one of the key technologies to ensure the safe and stable operation of equipment, and its importance is becoming increasingly prominent. Especially under extreme working conditions, how to ensure that the seals can withstand the test of harsh environments such as high temperature, high pressure, and corrosive media, while maintaining good sealing performance and long life has become the focus of common concern inside and outside the industry. Jiangsu Jintai Sealing Technology Co., Ltd., as a leader in the field of sealing technology, has successfully launched an innovative product, aramid filler, with its profound scientific research strength and rich production experience, bringing a new sealing solution to the market.

Aramid, the full name of aromatic polyamide fiber, is a polymer material with excellent properties such as high strength, high modulus, high temperature resistance, acid and alkali resistance. The application of aramid in the field of fillers not only inherits the excellent characteristics of its raw materials, but also gives aramid fillers more outstanding sealing performance and durability through special processing technology.

The aramid filler carefully developed by Jiangsu Jintai Sealing Technology Co., Ltd. uses high-quality aramid fiber as the base material and is made through multiple processes such as precision weaving and composite processing. Its unique fiber structure enables the packing to evenly distribute stress when under pressure, effectively preventing medium leakage; at the same time, the high temperature stability of aramid ensures that the packing can still maintain a stable sealing effect under extreme temperature conditions, and will not fail due to thermal expansion or thermal contraction.

In the current context of global advocacy of green development, Jiangsu Jintai Sealing Technology Co., Ltd. actively responds to national environmental protection policies and is committed to developing environmentally friendly sealing products. As an asbestos-free, non-toxic and environmentally friendly sealing material, aramid packing not only meets international environmental standards, but also greatly reduces the potential harm to the environment and human body. This feature makes aramid packing widely used in industries with high environmental requirements such as shipping, electricity, steel, and chemicals.

The excellent performance of aramid packing gives it a wide range of application prospects. In the shipping industry, aramid packing can effectively resist the erosion of corrosive media such as seawater and oil, and ensure the safe and stable operation of ship power systems and pipeline systems; in the power industry, high pressure and high temperature working conditions put forward extremely high requirements on sealing materials, and aramid packing has become an indispensable sealing element in the power transmission system with its excellent high temperature resistance and stable sealing effect.

Jiangsu Jintai Sealing Technology Co., Ltd. is well aware that innovation is the inexhaustible driving force for the development of enterprises. The company always puts scientific research and innovation first, continuously increases R&D investment, introduces advanced technologies and equipment at home and abroad, and improves the technological content and added value of products. In the process of developing aramid fillers, the company's scientific research team overcame one technical problem after another, and through continuous optimization of formulas and processes, the performance of aramid fillers has become more excellent and more in line with market demand.

Looking to the future, Jiangsu Jintai Sealing Technology Co., Ltd. will continue to adhere to the business philosophy of "quality first, customer first", guided by market demand and driven by scientific and technological innovation, and continue to launch more high-performance and environmentally friendly sealing products to contribute to the advancement of sealing technology in my country and even the world. As one of the representatives of the company's innovative achievements, aramid fillers will surely shine more brightly in the field of sealing technology in the future.

Eng

Eng  русский

русский