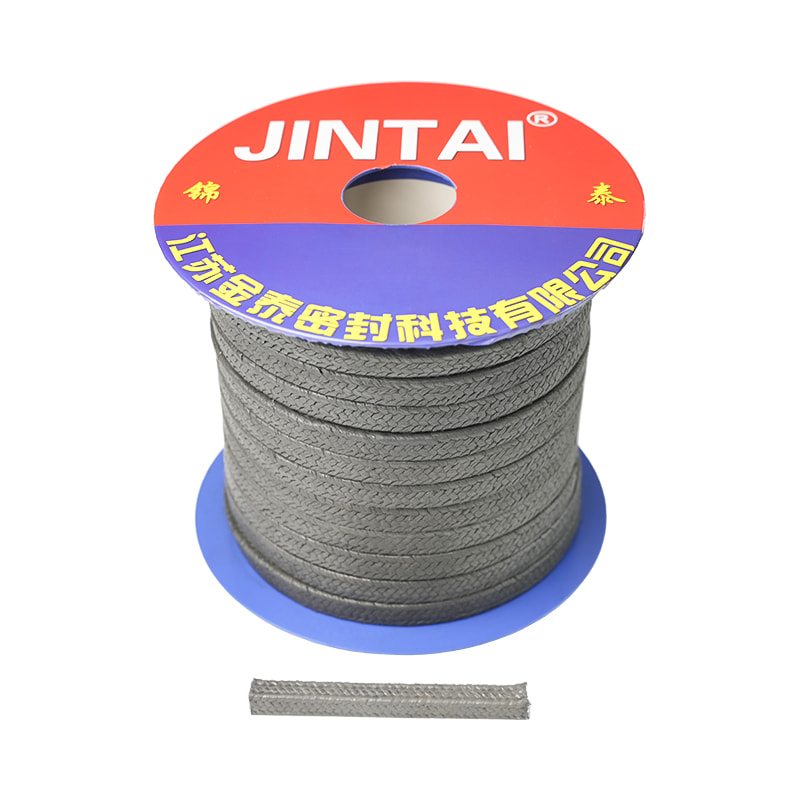

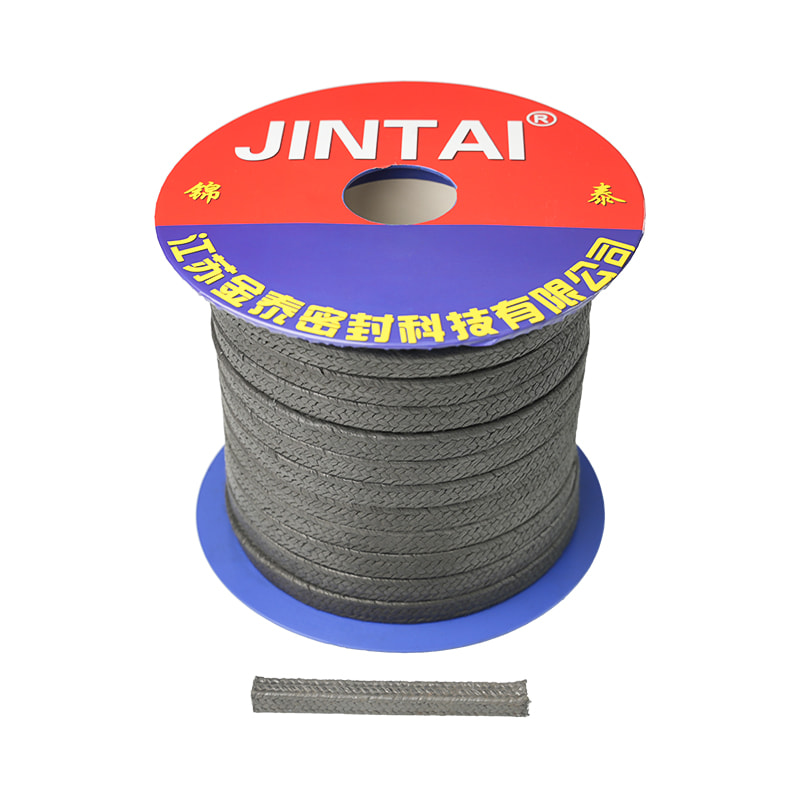

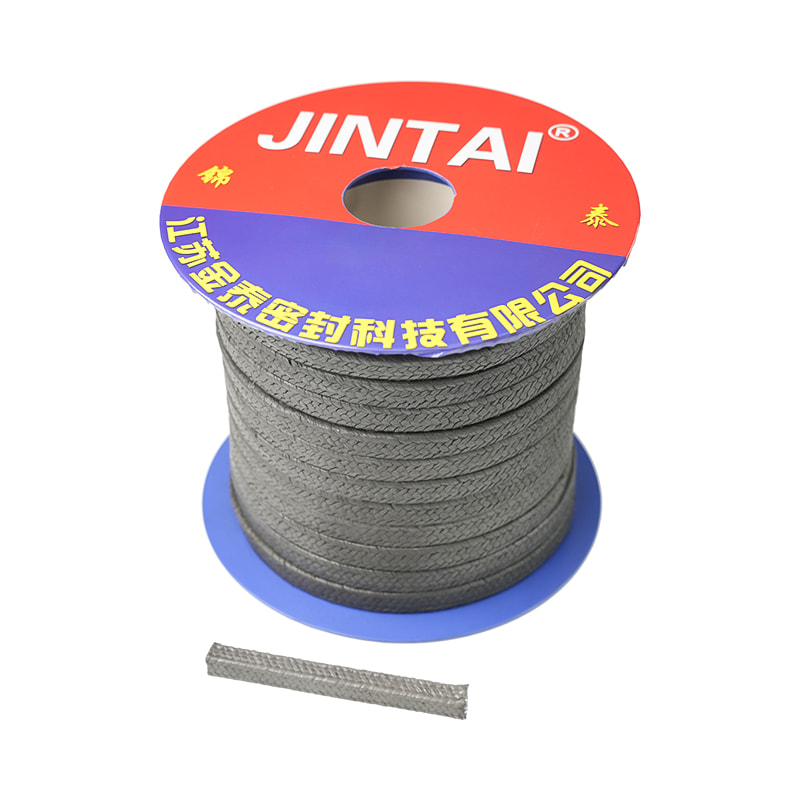

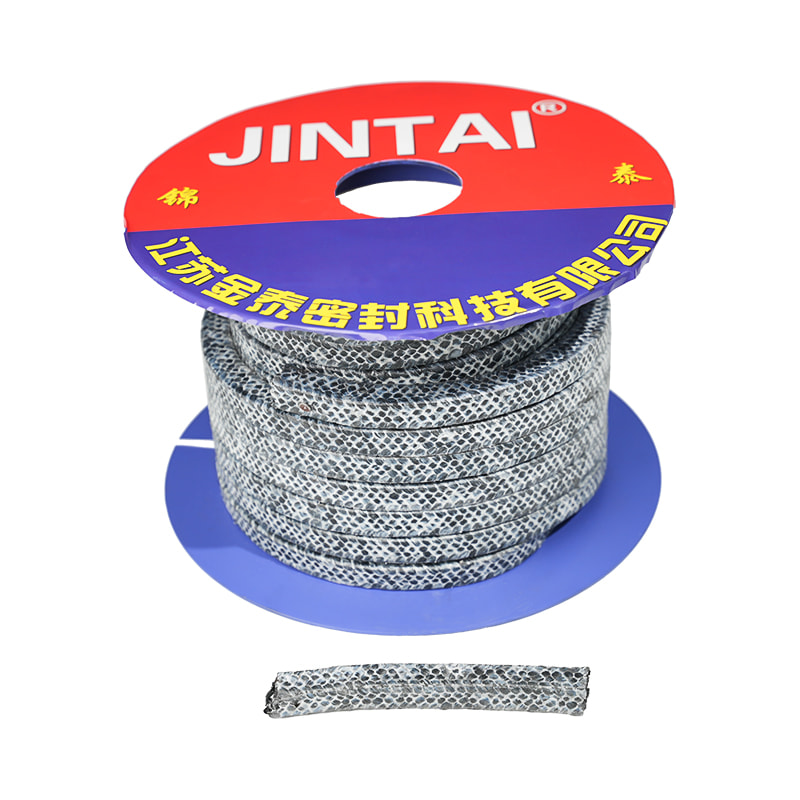

Mechanical/Water Pump PTFE Seal Packing Ramie Fiber Gland Packing

Ramie graphite packing is a packing made of ramie fiber treated with special technology and high-temperature lubricant. It is especially suitable for thermal power plant ash removal pumps, slurry pumps, front pumps water supply pump seals, and oil field high-pressure mud pumps. Mine emulsion pump seals.

Mechanical/Water Pump PTFE Seal Packing Ramie Fiber Gland Packing - Engineered for Reliable Sealing in Industrial Pumps

Product Features

- Material Composition: Constructed from PTFE and ramie fiber to provide chemical resistance and mechanical stability in pump sealing applications.

- Temperature and Pressure Resistance: Designed to withstand a broad range of operating temperatures and pressures, suitable for mechanical and water pumps.

- Durability and Wear Resistance: The gland packing maintains sealing integrity under continuous operation, reducing maintenance frequency and leakage risks.

Product Description

The PTFE Seal Packing with Ramie Fiber is engineered for use in mechanical and water pumps where reliable sealing and chemical compatibility are critical. Its design minimizes leakage and maintains consistent performance across variable temperature and pressure conditions.

Manufactured according to recognized industrial standards, the product exhibits stable physical and chemical properties. The combination of PTFE and ramie fiber provides dimensional stability, resistance to abrasion, and compatibility with various pump media, ensuring efficient operational continuity in industrial environments.

Applications

This seal packing is suitable for the following industrial scenarios:

- Mechanical water pumps in industrial fluid handling systems

- Chemical processing pumps requiring chemical-resistant gland packing

- Pump maintenance and retrofitting for leakage control in municipal or industrial water systems

FAQ

1. What types of pumps are compatible with PTFE Seal Packing with Ramie Fiber?

This packing is compatible with mechanical and water pumps, including centrifugal, rotary, and chemical process pumps where moderate to high temperatures and pressures are encountered.

2. How do I determine the correct size of gland packing for my pump?

Measure the stuffing box dimensions of your pump accurately, including width, depth, and bore diameter. Consult the technical specifications table to select the appropriate thickness and length for optimal sealing performance.

3. Can this gland packing handle aggressive chemical media?

Yes, the combination of PTFE and ramie fiber provides chemical resistance suitable for a range of aqueous and mildly corrosive media. For highly aggressive chemicals, verify compatibility with the specific chemical type and concentration before application.

Specifications

|

Temperature |

-40℃-+140℃ |

||

|

Pressure |

3Mpa(Rotary pump) |

5Mpa(Reciprocating pump) |

12Mpa(Valve) |

|

PH Value |

5-12 |

|

|

|

Line speed |

10M/S(Rotary pump) |

2M/S(Reciprocating pump) |

2M/S(Valve) |

|

Available cross-section sizes |

≥1/8”~≤3”(3x3-75x75mm) |

||

|

Density |

1.30~1.40g/cm³ |

||

|

Note: (1) The packing can be penetrated with high-temperature lubricant as needed. Density: 1.50-1.65g/cm³ (2) Iron red silicone strip elastomer can be added to the core of the packing as needed. |

|||

KEEP IN TOUCH

-

In high-utility power generation, the integrity of a steam turbine relies heavily on the performance of its static sealing interfaces. A metal gasket ring is often the first line of defense against ca...

READ MORE -

In the demanding landscape of industrial fluid handling, maintaining seal integrity in high-temperature environments is a paramount challenge for engineers. As centrifugal pumps and valves operate und...

READ MORE -

In high-pressure and high-temperature industrial environments, achieving a hermetic seal is paramount for operational safety and environmental compliance. The corrugated graphite gasket has emerged as...

READ MORE

With the transformation of traditional industrial materials, how has Jiangsu Jintai's ramie filler become a green pioneer?

Today, when environmental protection and sustainable development have become a global consensus, traditional industrial materials are undergoing a profound transformation. In this transformation, Jiangsu Jintai Sealing Technology Co., Ltd. has led the green revolution in the field of sealing materials with its unique ramie filler products, providing efficient and environmentally friendly solutions for multiple industries.

Jiangsu Jintai Sealing Technology Co., Ltd., located on Xingyuan Road, Yuanzhu Industrial Park, Taixing City, Jiangsu Province, has been driven by technological innovation and deeply engaged in the field of sealing technology since its establishment in 2004. Years of scientific research and production accumulation have not only enabled the company to have a complete quality management manual and monitoring system, but also enabled it to occupy a place in the sealing material market. Among them, ramie filler, as the company's star product, has won wide acclaim in the market for its unique performance and wide range of applications.

Ramie, as a natural plant fiber, has excellent moisture absorption, air permeability and corrosion resistance, and is an ideal choice for making environmentally friendly sealing materials. Jiangsu Jintai Sealing Technology Co., Ltd. uses advanced production processes and technical means to finely process ramie fibers to produce ramie fillers with excellent performance. This filler not only retains the natural advantages of ramie, but also improves its sealing performance, high temperature resistance and chemical corrosion resistance through scientific formula design, perfectly meeting the high requirements of sealing materials in multiple industries such as shipping, power, steel, chemical industry, machinery, etc.

Today, with the increasing awareness of environmental protection, Jiangsu Jintai Sealing Technology Co., Ltd. is well aware of its responsibilities. The company is committed to promoting environmentally friendly asbestos-free gaskets, and ramie filler is one of the best. Compared with traditional asbestos fillers, ramie fillers are not only non-toxic and harmless, but also degradable and recyclable, which greatly reduces the pollution to the environment. This green and environmentally friendly production concept not only conforms to the national policy orientation for the environmental protection industry, but also wins the trust and support of customers.

Over the years, Jiangsu Jintai Sealing Technology Co., Ltd. has successfully formed a close supporting relationship with multiple industries such as shipping, power, steel, chemical industry, machinery, etc. with its professional R&D capabilities, excellent product quality and perfect after-sales service system. In these industries, ramie fillers have become the preferred sealing material for many companies with their excellent performance and wide range of applications. Whether it is a harsh environment of high temperature and high pressure, or complex and changeable working conditions, ramie filler can show its unique advantages and contribute to the safe production and energy conservation and emission reduction of enterprises.

Looking to the future, Jiangsu Jintai Sealing Technology Co., Ltd. will continue to adhere to the development concept of "innovation, environmental protection, high efficiency, and win-win", with ramie filler and other environmentally friendly sealing materials as core products, and continue to expand new application fields and market space, and contribute to the development of environmental protection industry in my country and even the world. In this wave of green revolution, Jiangsu Jintai Sealing Technology Co., Ltd. will undoubtedly become a shining star, leading the future development direction of the sealing material industry.

Eng

Eng  русский

русский