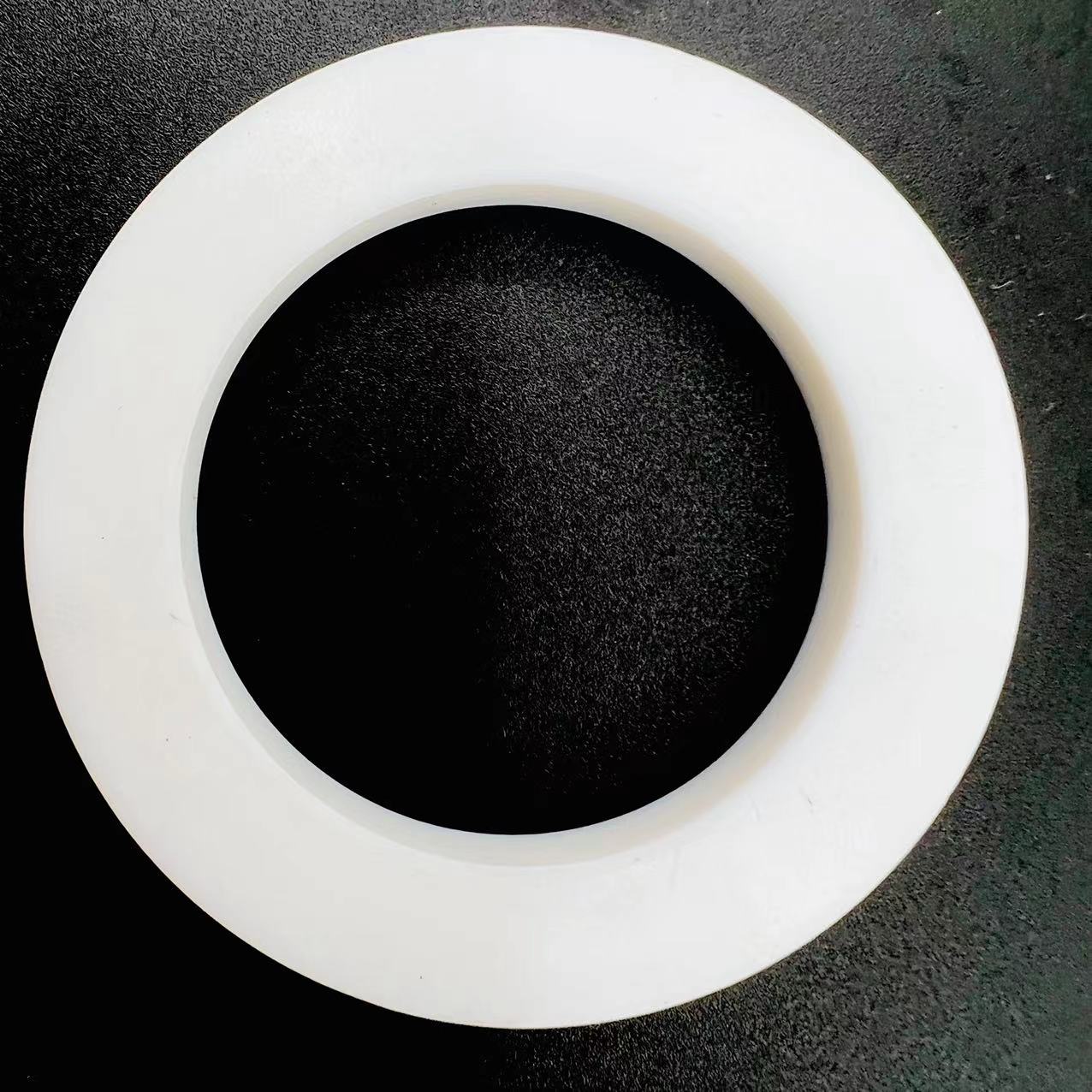

White -270℃-315℃ Non Metallic Expanded PTFE Ring Gasket

Expanded polytetrafluoroethylene (ePTFE) Mifu gasket adopts a strong porous structure, which greatly improves the tensile strength and heat resistance of PTFE, as well as its softness and better chemical resistance, making it suitable for various chemicals. Our company can supply pipeline flanges for products and acid-base solutions and gaskets for valve seals in various sizes at any time.

As the better substitute for traditional asbestos and hard pure PTFE gaskets, expanded polytetrafluoroethylene (ePTFE) sealing sheets are currently the plate seals with better creep and cold flow resistance among all PTFE materials. It requires a small tightening force (2 bar) and can withstand considerable internal pressure in a changing pressure environment. It is suitable for sealing applications of more than any chemicals or chemical processes below 315°C. Expanded polytetrafluoroethylene (ePTFE) gaskets are not affected by steam and cannot withstand rapid temperature cycle changes, so they are also an ideal sealing material for boiler fluid delivery pipelines.

The expanded polytetrafluoroethylene (ePTFE) gasket is a high-density fiber structure. After being compressed, the high-density fiber structure will tangle with each other to form a dense "solid-like" texture that is airtight and watertight. It is still soft and stable in performance after high pressure or long-term pressure. It always maintains high tensile strength. Because of its better creep resistance, it can always maintain better sealing. This product is available in various widths and thicknesses and can be quickly and easily processed without cutting in advance, so it can be constructed on-site. The sealing effect is better than traditional hard pure PTFE gaskets and the required tightening force is low. It can be applied to all metal, plastic and various fragile flange seals. It can also be combined with natural tooth-shaped metal sheets to make new tooth-shaped sealing gaskets suitable for high-temperature and high pressure working conditions.

White -270℃ - 315℃ non-metallic expanded polytetrafluoroethylene (PTFE) ring gasket, pure appearance, made with advanced technology, expanded PTFE material gives it extraordinary chemical stability, and can remain stable even in harsh chemical environments such as strong acids and alkalis. It has a wide temperature range, from extremely cold -270℃ to high temperatures of 315℃, it can work normally and effectively prevent leakage. It has excellent sealing performance and is widely used in industries with strict sealing requirements such as chemical, food, pharmaceutical, aerospace, etc.

Product Features

Temperature range: can be used in extreme temperatures from -270℃ to +315℃.

Chemical resistance: resistant to almost all chemical media, including strong acids, strong alkalis, solvents and organic compounds.

Low creep and cold flow: the unique expansion process eliminates the creep and cold flow problems of traditional PTFE materials, ensuring stable sealing performance.

Applicable media: suitable for media such as steam, strong acids, strong alkalis, aqueous hydrogen chloride solution and anhydrous hydrogen fluoride.

Easy installation: soft and easy to cut, can adapt to rough or irregular flange surfaces.

This product is widely used in the following fields:

Chemical industry: used for sealing equipment such as pipelines, valves, pumps, pressure vessels, etc.

Petrochemical industry: suitable for high temperature and high pressure conditions in refineries and chemical plants.

Food and pharmaceutical industry: due to its chemical resistance and non-polluting characteristics, it is suitable for environments with strict hygiene requirements.

Aerospace: used for sealing aircraft engines, fuel systems and hydraulic systems.

Ship industry: suitable for steam pipes and fluid delivery systems of ships.

Specifications

|

Color |

White |

|

Applicable temperature range |

-270℃-315℃ |

|

Pressure, max. |

200bar |

|

Density |

0.8g/cm³ |

|

Applicable fluid media |

Steam, strong acid, strong base, aqueous hydrogen chloride solution and anhydrous hydrogen fluoride |

|

Fluid pH range |

1/14 |

|

Compression ratio, ASTM F36 |

50% |

|

Rebound rate, ASTM F36 |

12% |

KEEP IN TOUCH

-

I. Sealing Solutions for Extreme Industrial Environments In critical industrial applications—spanning shipping, power generation, iron and steel, and chemistry—the integrity of dynamic seals is paramo...

READ MORE -

In critical industrial applications—from power generation to petrochemical processing—the performance of pure graphite gland packing is measured by its ability to reliably contain media across extreme...

READ MORE -

For industrial operations in power generation, chemical processing, and steel manufacturing, the integrity of a sealed joint operating under extreme thermal conditions is paramount. Failure of a **Hig...

READ MORE

Revolutionizing Sealing Solutions: The Rise of Expanded PTFE - A Material to Question Traditional Norms?

In the field of modern industry, seals are key components to ensure the safe and stable operation of equipment, and their performance is directly related to production efficiency and product quality. With the advancement of science and technology and the improvement of environmental awareness, traditional sealing materials such as asbestos and hard pure PTFE are no longer able to meet the increasingly stringent industrial needs. In this context, expanded polytetrafluoroethylene (ePTFE), as a new high-performance sealing material, is gradually becoming the first choice in many industries due to its unique physical and chemical properties and excellent sealing performance.

Expanded polytetrafluoroethylene, or Expanded PTFE for short, is a PTFE material formed into a strong porous structure through special processing. This innovative design not only retains the original excellent chemical resistance, low friction coefficient and wide temperature adaptability of PTFE ( -240°C to +260°C, up to 315°C under certain conditions), and also significantly improves its tensile strength, heat resistance and creep resistance. Compared with traditional PTFE gaskets, ePTFE gaskets exhibit a more stable and reliable sealing effect under high pressure, high temperature and complex chemical environments.

As an alternative to traditional asbestos and hard pure PTFE gaskets, ePTFE seals stand out for their excellent resistance to creep and cold flow. In terms of tightening force requirements, ePTFE gaskets require only a low tightening force (about 2 bar) to achieve effective sealing, which greatly reduces installation difficulty and cost. At the same time, its excellent chemical resistance makes ePTFE gaskets suitable for sealing needs in almost all chemicals or chemical processes, including extreme environments such as strong acid and strong alkali, providing a safer and more reliable solution for the chemical, petroleum, pharmaceutical and other industries. solution.

The high-density fiber structure of ePTFE gaskets is at the core of its superior performance. When subjected to pressure, these fibers tangle with each other to form a dense "solid-like" structure that effectively blocks the penetration of gases and liquids. This structure not only ensures the flexibility and stability of the gasket under high pressure or long-term pressure, but also enables it to always maintain high tensile strength, thereby ensuring the durability of the sealing effect. In addition, the creep resistance of ePTFE gaskets is also extremely good, and it can maintain a good sealing state and avoid the risk of leakage even in environments with large temperature fluctuations.

In order to meet the needs of different industrial scenarios, ePTFE gaskets provide a variety of width and thickness options. They can be processed quickly and easily without prior cutting, greatly improving construction efficiency. The ease of on-site application makes ePTFE gaskets particularly popular for emergency repair and retrofit projects. In addition, ePTFE gaskets can also be used in combination with natural tooth-shaped metal sheets to create new tooth-shaped sealing gaskets suitable for high temperature and high pressure working conditions, further broadening its application scope.

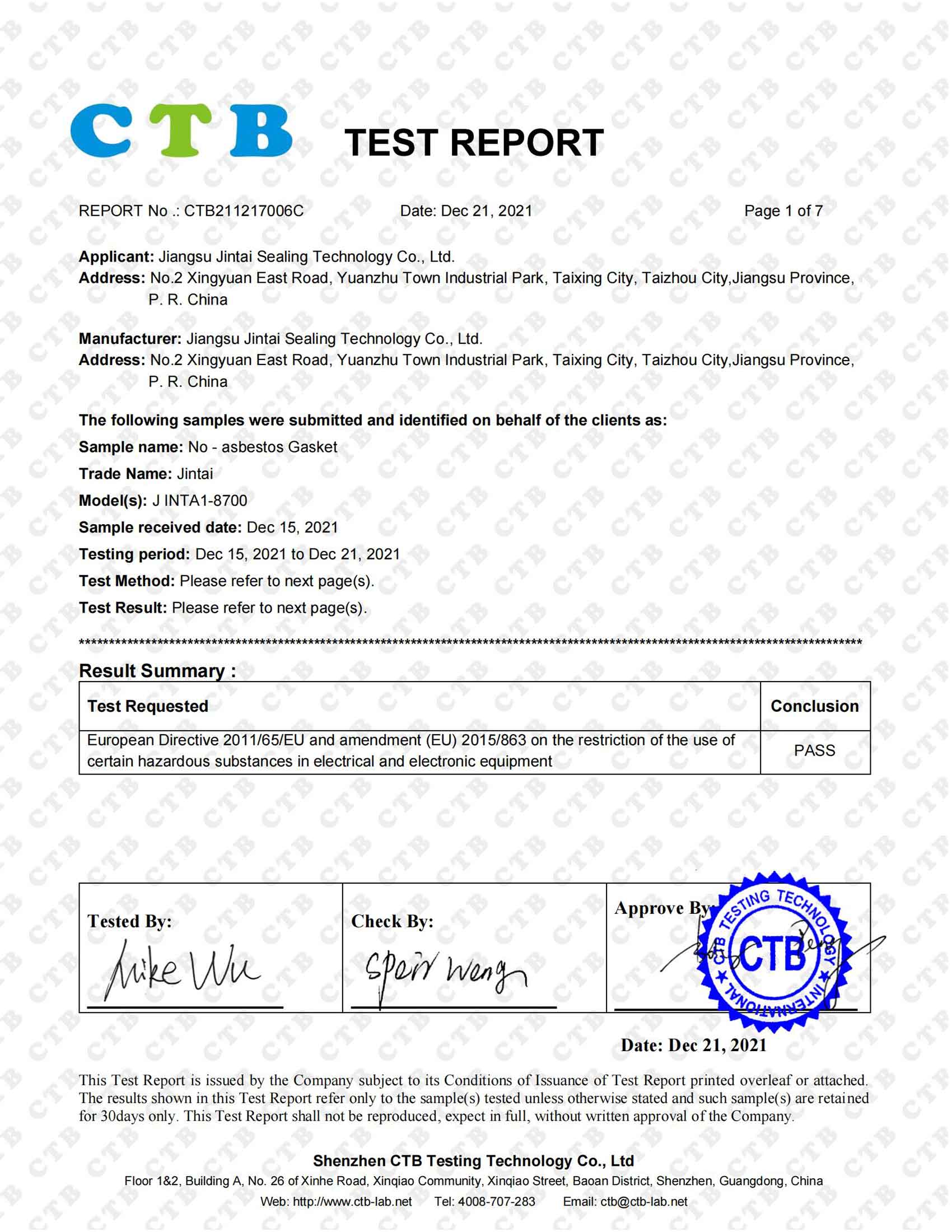

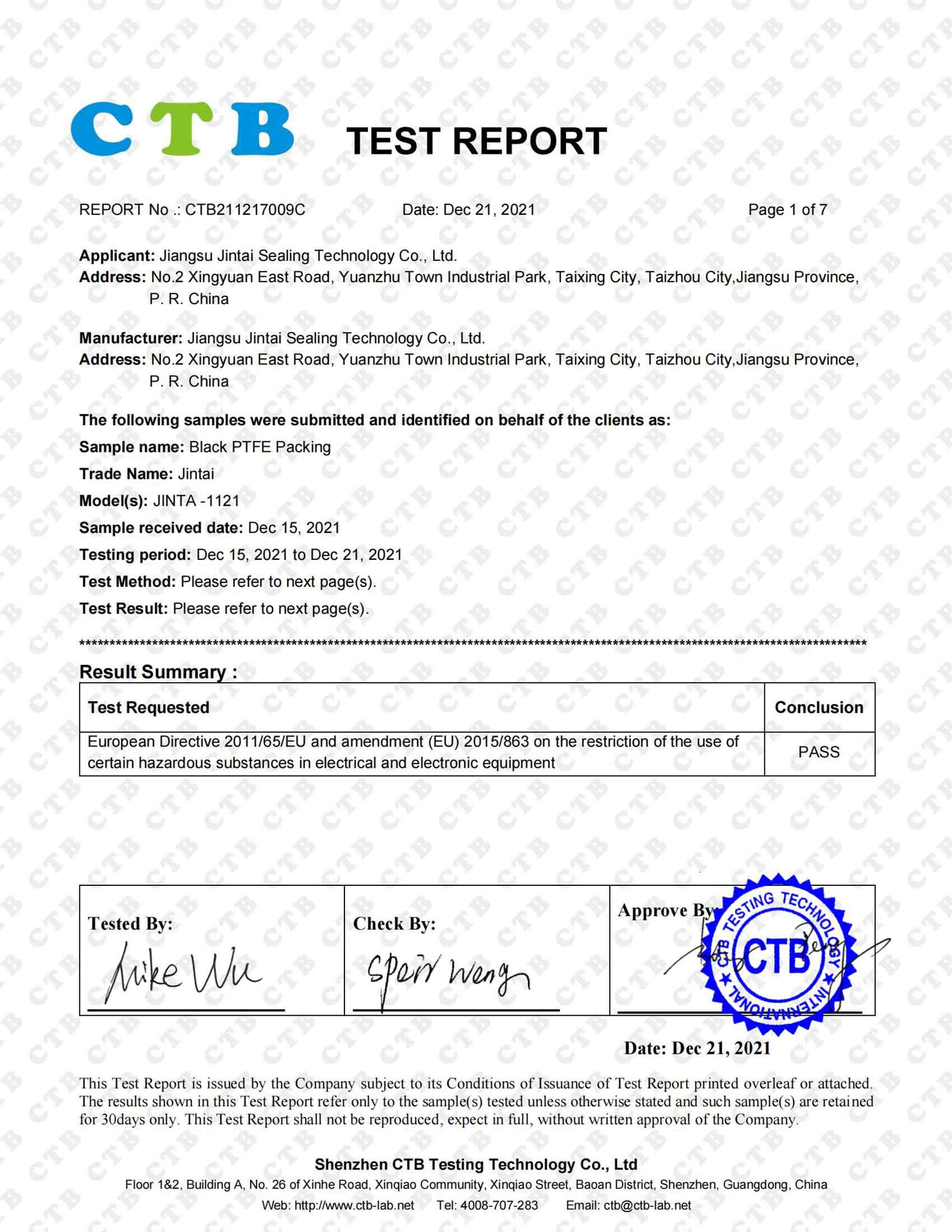

As a leading supplier of customized sealing gaskets, sealing fillers, and rubber products in China, Jiangsu Jintai Sealing Technology Co., Ltd. has always been at the forefront of sealing technology. Relying on its strong R&D strength and rich production experience, the company continues to launch high-performance sealing products that meet market demand. As one of the company's key products, ePTFE gaskets have been widely used in many industries such as shipbuilding, electric power, steel, chemicals, and machinery, and have won widespread praise from customers.

As a bright new star in the field of sealing materials, expanded polytetrafluoroethylene (ePTFE) is leading the transformation of the industry with its excellent performance and wide application prospects. With the continuous advancement of technology and the continued growth of market demand, ePTFE gaskets will surely show their unique value in more fields, providing a solid guarantee for industrial safety and efficient operation. As a leader in this field, Jiangsu Jintai Sealing Technology Co., Ltd. will continue to adhere to the concepts of innovation, pragmatism and efficiency to provide customers with more high-quality and reliable sealing solutions.

Eng

Eng  русский

русский