Rubber Seal Gasket: The Essential Component for Sealing and Protection

2025.01.09

2025.01.09

Industry News

Industry News

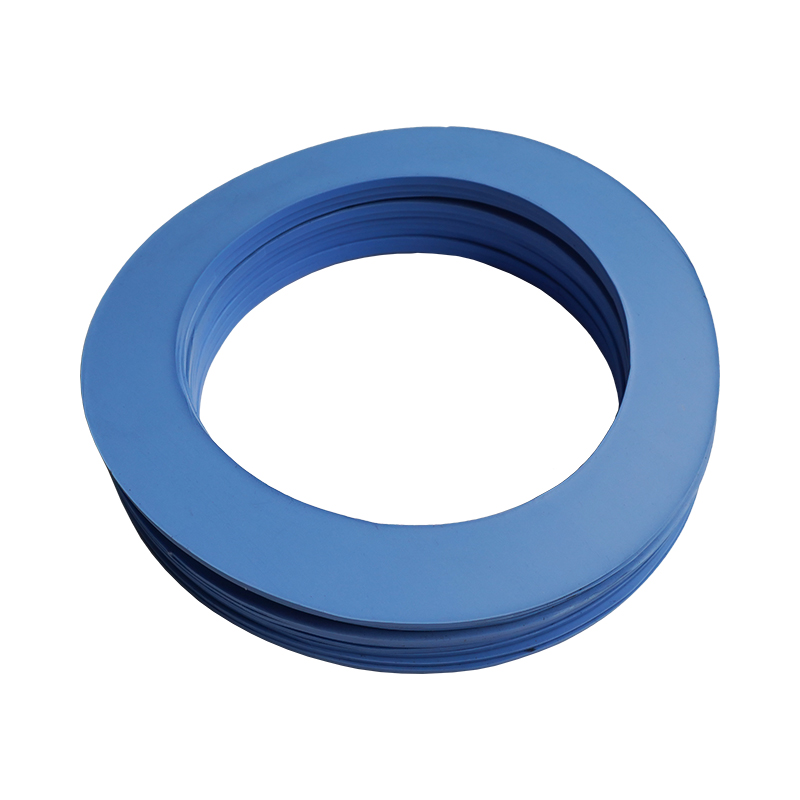

A rubber seal gasket is a mechanical seal made of flexible rubber material that is shaped to fit specific applications. It is usually positioned between two surfaces to prevent the passage of liquids, gases, or other substances. The rubber used in these gaskets has excellent sealing properties, such as flexibility, resistance to chemicals, high compression resistance, and durability.

These gaskets are available in a wide variety of materials, such as EPDM (Ethylene Propylene Diene Monomer), Nitrile Rubber (NBR), Silicone Rubber, Viton, and Neoprene, depending on the application requirements. The choice of material is crucial in determining the gasket's compatibility with the substances it will come into contact with, as well as its ability to withstand temperature changes, pressure, and wear.

Types of Rubber Seal Gaskets

There are several types of rubber seal gaskets, each designed for specific applications. Some of the most common types include:

O-Rings: One of the most widely used rubber gaskets, O-rings are circular and designed to fit into grooves between two surfaces. They provide a reliable seal by compressing under pressure.

Flat Gaskets: These gaskets are flat and can be used for sealing larger surfaces. They are used in various industries, including automotive, plumbing, and manufacturing.

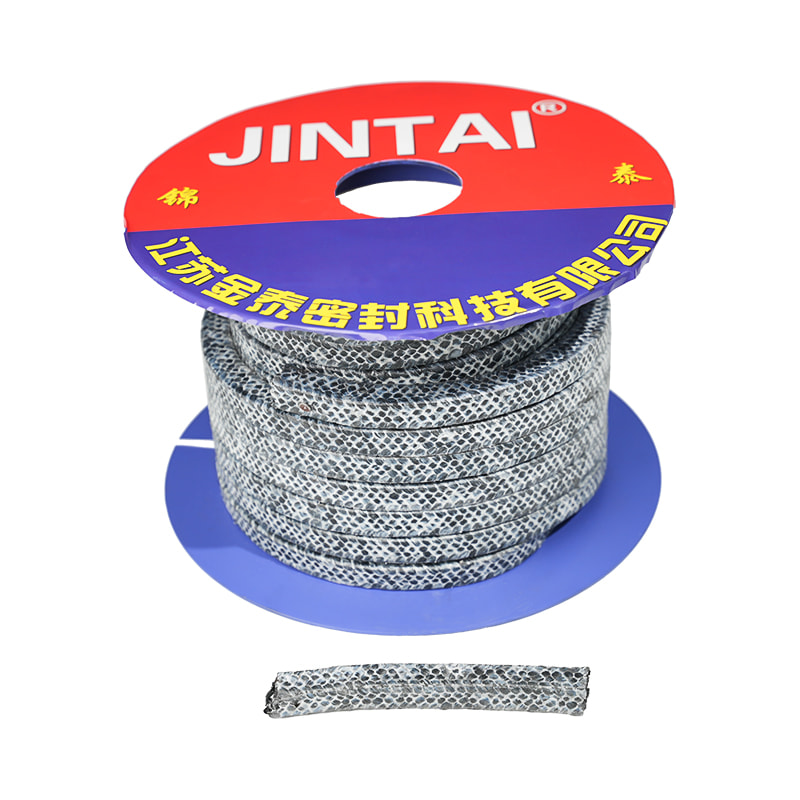

Cork Rubber Gaskets: These gaskets combine the compressibility of cork with the flexibility of rubber, making them ideal for applications where high compression and sealing are required.

Gasket Sheets: Gasket sheets are flat rubber sheets used to create custom gaskets. They are often used in large industrial applications or when a specific gasket shape is required.

Lip Seals: These seals are used to prevent leakage in rotary or moving parts, such as shafts, bearings, and pumps.

Applications of Rubber Seal Gaskets

Rubber seal gaskets are found in numerous industries, where they provide essential sealing and protection. Some of the most common applications include:

Automotive Industry: Rubber gaskets are crucial in car engines, transmission systems, and exhaust systems. They prevent fluid leaks, such as oil or coolant, and protect sensitive engine components from dirt and debris.

Plumbing and HVAC: In plumbing and heating, ventilation, and air conditioning (HVAC) systems, rubber gaskets are used to seal pipes, valves, and joints to prevent water, gas, or air leaks.

Aerospace: Rubber gaskets are used to maintain airtight seals in airplanes and spacecraft. These gaskets ensure the integrity of fuel systems, hydraulic systems, and other essential components.

Food and Beverage: In the food industry, rubber seals are used in packaging equipment, refrigerators, and production lines to ensure that the products are sealed from contamination and maintain hygiene standards.

Industrial Machinery: Rubber gaskets are used in pumps, compressors, and other machinery to prevent leaks of fluids or gases that could affect the efficiency and safety of operations.

Why are Rubber Seal Gaskets Important?

Rubber seal gaskets are essential for several reasons:

Leak Prevention: They prevent the leakage of gases, liquids, or chemicals, which is critical in industries such as automotive, chemical processing, and oil and gas.

Protection Against Contaminants: Gaskets provide a barrier that keeps contaminants, such as dust, dirt, and moisture, from entering sensitive areas, such as engines and electronics.

Durability: Rubber gaskets are durable and can withstand extreme temperatures, pressure, and mechanical stress. This durability helps to extend the lifespan of machinery and equipment.

Improved Performance: By ensuring a tight seal, rubber gaskets help optimize the performance of mechanical systems. They reduce friction and wear, allowing equipment to run smoothly and efficiently.

Energy Efficiency: Sealing off leaks in systems like HVAC and refrigeration can lead to energy savings, as the system can maintain its performance without wasting energy.

Eng

Eng  русский

русский