Wide application of PTFE packing sealing technology in valve and pump systems

2024.10.17

2024.10.17

Industry News

Industry News

The application of PTFE (polytetrafluoroethylene) packing seals in valve and pump systems has attracted more and more attention from the industry. Especially in the fields of chemical, petroleum, pharmaceutical and other fields that require strict sealing performance, PTFE packing has become a popular solution due to its excellent chemical resistance, high temperature resistance and self-lubricating properties.

Advantages of white pure PTFE packing

Compared with traditional sealing materials, white pure PTFE packing has a series of outstanding technical advantages:

Excellent chemical corrosion resistance

PTFE is one of the most corrosion-resistant materials known to date, and can resist almost all chemical corrosion, which makes it the best choice in the environment of corrosive media.

Excellent high temperature resistance

PTFE can maintain its mechanical properties in a wide temperature range of -200°C to 260°C, which is suitable for sealing needs under extreme temperature conditions.

Low friction coefficient

Due to the self-lubricating properties of PTFE, its friction coefficient is extremely low, which can effectively reduce the wear of equipment during operation and increase the service life of valves and pumps.

Non-polluting

White pure PTFE filler does not contain any impurities or additives and can be used safely in fields such as food and medicine that require extremely high sanitary conditions. In addition, PTFE filler does not pollute the environment and is an environmentally friendly material.

Wide range of applications

In the sealing applications of valves and pumps, white pure PTFE filler exhibits excellent sealing performance and durability. It can not only effectively prevent liquid or gas leakage, but also ensure the stable operation of the system under high pressure or high temperature conditions. Especially in industries such as petrochemicals, papermaking, and metallurgy, the reliability of the sealing system directly affects the operating efficiency of the equipment. PTFE filler has significantly improved the sealing performance and service life of the system with its excellent durability and adaptability.

With the advancement of industrial automation and equipment modernization, PTFE filler will continue to play a key role in complex working conditions. High efficiency and energy saving, reliability and low maintenance costs have become important criteria for various industries to select sealing materials. White pure PTFE filler not only meets these requirements, but also has excellent long-term durability, and is expected to play a more important role in future industrial applications.

White pure PTFE filler occupies an important position in the field of sealing technology with its excellent performance. It provides a solid guarantee for the long-term reliable operation of valves and pumps, and has become the preferred sealing solution for more and more industries.

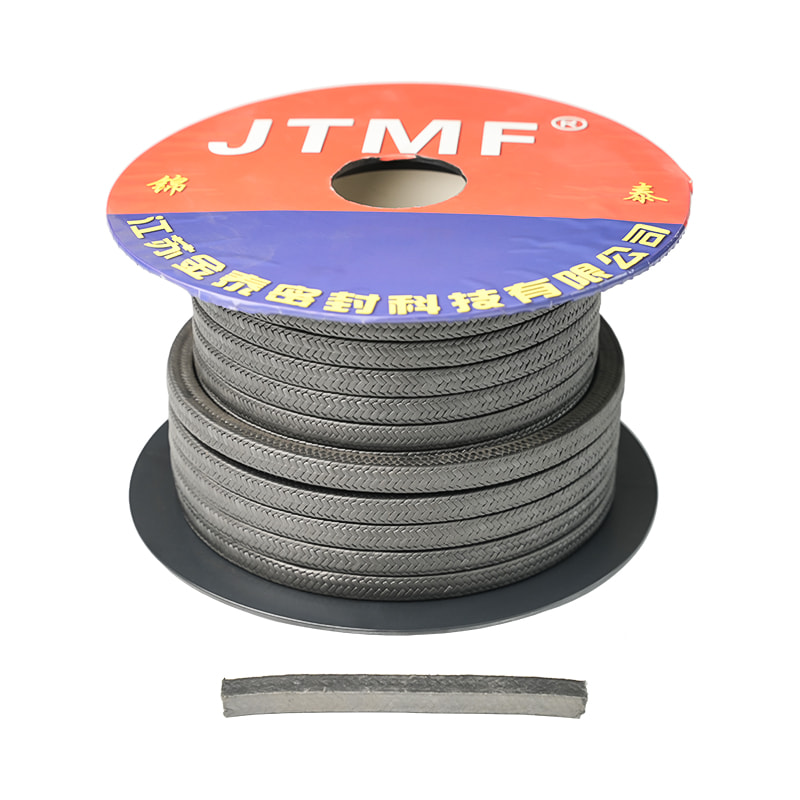

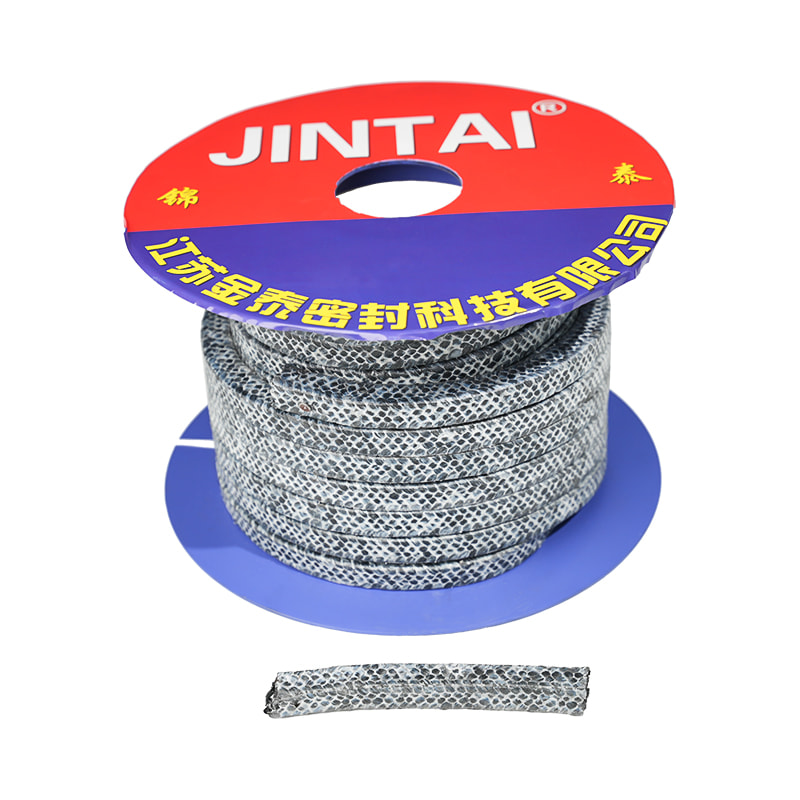

Valves Pump Gland Packing Seals White Pure PTFE Gland Packing

Eng

Eng  русский

русский