How do stainless steel sealing rings and corrugated metal gaskets improve the safety and reliability of equipment in high temperature and high pressure environments?

2024.12.26

2024.12.26

Industry News

Industry News

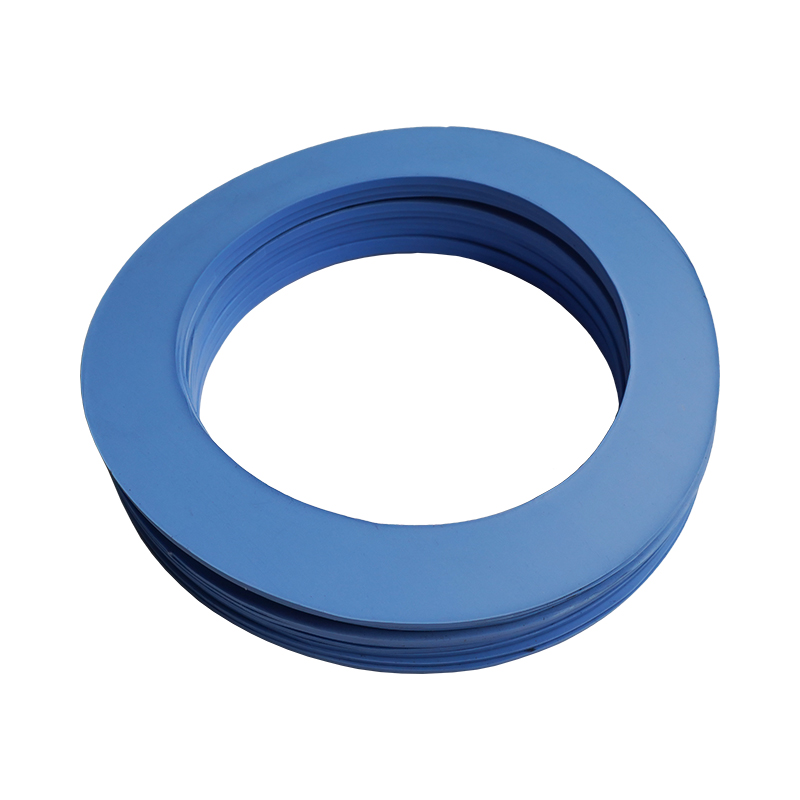

The adaptability of the stainless steel sealing ring corrugated metal gasket gives it significant advantages in high temperature and high pressure environments, and can significantly improve the safety and reliability of the equipment. Here are a few key factors:

High temperature resistance: Stainless steel material itself has excellent high temperature resistance and can withstand operating temperatures up to 800°C or more (depending on the type of stainless steel). The design of the corrugated metal gasket allows it to maintain good sealing performance during thermal expansion, preventing leakage or damage in high temperature environments.

High-pressure resistance: The corrugated structure of corrugated metal gaskets can provide stronger elasticity and recovery in high-pressure environments. When subjected to high pressure, the corrugated structure of the gasket can effectively fill the uneven contact surface, ensuring that the sealing performance is not affected by compression, thereby avoiding equipment leakage or failure caused by poor sealing.

Adaptability: Corrugated metal gaskets have good adaptability and can adapt to minor unevenness on the contact surface under high temperature and high pressure. This adaptive feature can help maintain long-term sealing effect and reduce sealing failure caused by long-term operation of the equipment or wear of the contact surface.

Corrosion resistance: Stainless steel has good corrosion resistance and is especially suitable for use in chemical media environments. Even under high temperatures and pressures, gaskets resist corrosion and oxidation, extending the service life of equipment and ensuring safe operation.

Enhanced safety: By providing a stable and reliable seal in high-pressure and high-temperature environments, corrugated metal gaskets can effectively prevent gas, liquid or steam leakage, thereby greatly reducing the risk of equipment failure, fire or explosion, and significantly improving the safety of industrial equipment. Safety and job stability.

Eng

Eng  русский

русский