Rubber Gasket is a multifunctional sealing gasket

2024.05.08

2024.05.08

Company News

Company News

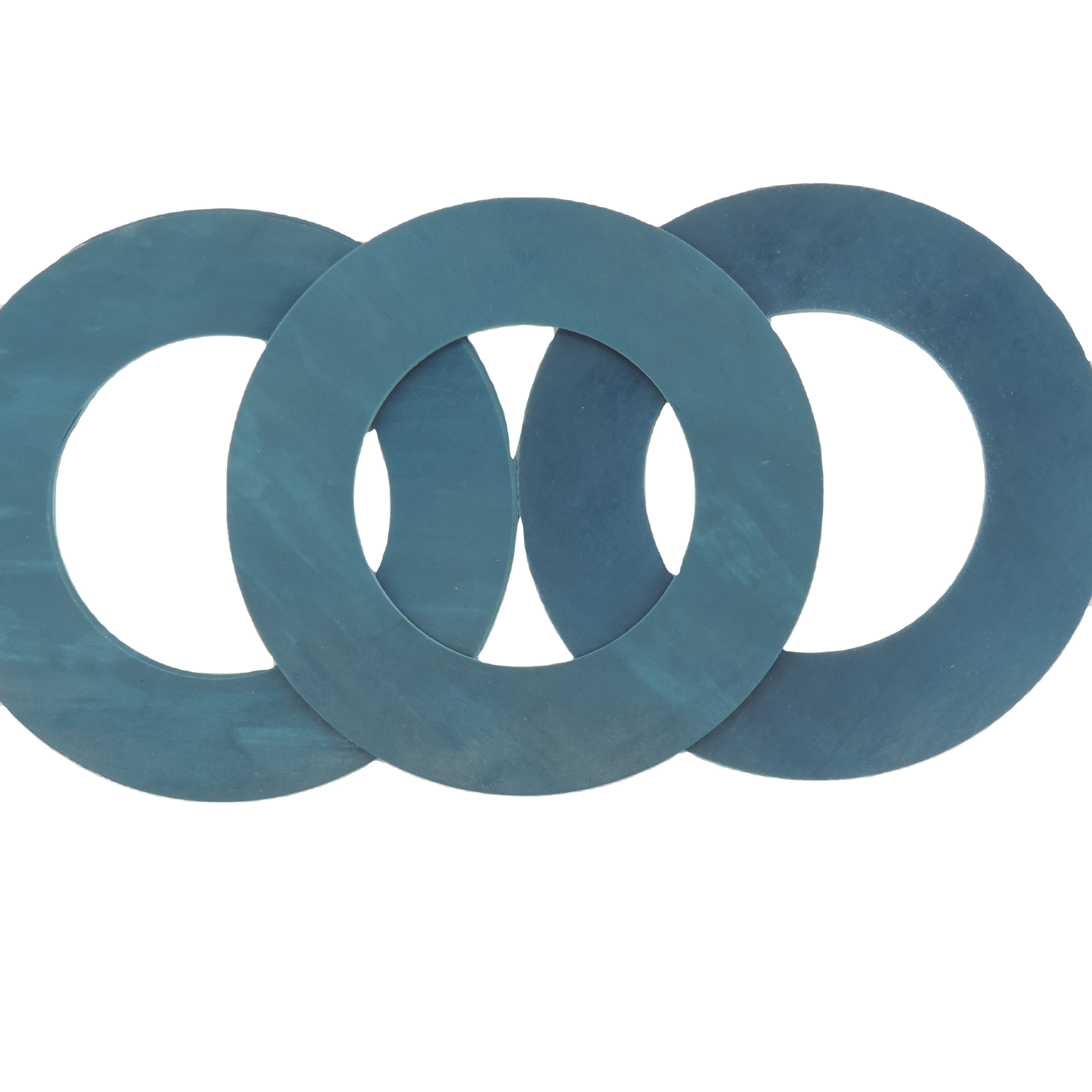

Introduction to Rubber Gasket

Rubber Gasket, also known as rubber gasket, is a common sealing material. They are usually used between two connecting parts to prevent the leakage of gas or liquid. Due to the elasticity and durability of rubber, Rubber Gasket has a wide range of applications in many industries.

Advantages of Rubber Gasket

Good sealing performance

Due to its good elasticity, Rubber Gasket can fill and adapt to irregular spaces between connected parts when installed, thus providing better sealing performance.

Durability

Rubber is a very durable material that resists wear, tear, and aging. As a result, Rubber Gasket maintains its performance and integrity in a variety of environmental conditions.

Diversity

Rubber gaskets can be manufactured in a variety of shapes and sizes depending on specific application needs. In addition, by using different types of rubber (such as silicone rubber, fluoroelastomer, etc.), Rubber Gaskets can be manufactured with different performance characteristics.

Application of Rubber Gasket

Due to its advantages, Rubber Gasket has a wide range of applications in many industries. For example, in the automotive industry, a rubber gasket is used in components such as engines, exhaust systems, and fuel systems to prevent leaks of liquids and gases. In piping systems, a rubber gasket is used to connect pipes to ensure the tightness of the system. In electronic equipment, Rubber Gasket is used to prevent dust and moisture from entering the interior of the equipment.

Rubber Gasket is a versatile sealing gasket whose advantages make it widely used in many industries. Whether in automobiles, piping systems, or electronic equipment, Rubber Gasket plays an important role.

Eng

Eng  русский

русский