Graphite Gland Packing meets chemical equipment sealing challenges

2024.08.29

2024.08.29

Industry News

Industry News

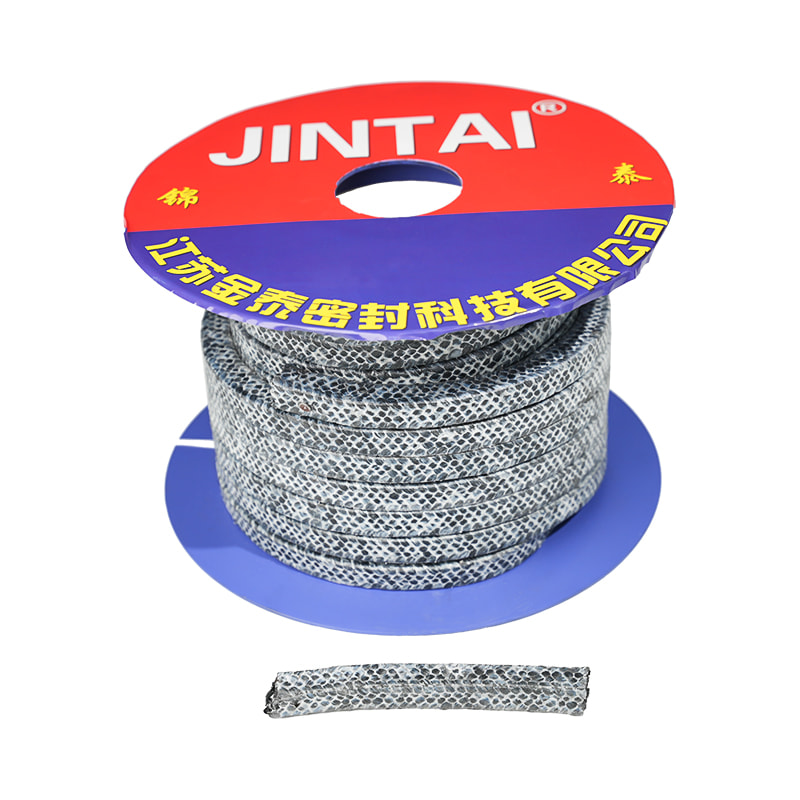

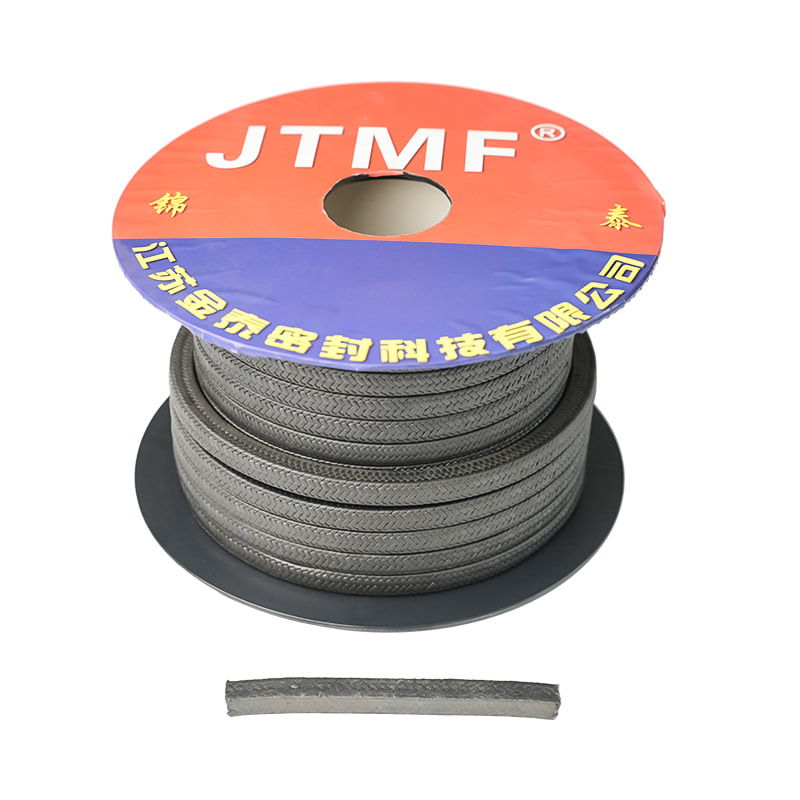

Graphite Gland Packing has demonstrated unique advantages and remarkable results in meeting the sealing challenges of chemical equipment. Here's a detailed analysis of how it addresses these challenges:

1. Coping with high pressure and high temperature environment

1. High temperature resistance

Graphite Gland Packing is made of high-purity graphite, and the graphite material itself has extremely high temperature resistance. In chemical equipment, especially those that need to handle high-temperature fluids, Graphite Gland Packing can maintain the stability of its structure and is not easy to melt or deform, thereby ensuring the sealing effect. This makes it one of the ideal sealing materials in high pressure and high temperature environments.

2. High pressure resistance

Graphite Gland Packing also performs well under high-pressure conditions. Its high strength and excellent compression resistance enable it to maintain a stable sealing effect under high pressure conditions. In addition, the low friction coefficient and high sliding speed of graphite material also reduce the heat and wear caused by friction, further improving the reliability of the seal.

2. Coping with corrosive media

1. Corrosion resistance

Chemical equipment often needs to handle various corrosive media, which places extremely high demands on sealing materials. Graphite Gland Packing has excellent corrosion resistance to a variety of chemical substances, including corrosive media such as acids, alkalis, and salts. This enables it to operate stably for a long time in chemical equipment that handles corrosive fluids without failure due to media corrosion.

3. Self-lubricating properties reduce wear

1. Self-lubricating property

Graphite Gland Packing has good self-lubricating properties, which means that it does not require additional lubricant to maintain a low coefficient of friction during the sealing process. This self-lubricating property not only reduces heat and wear due to friction, but also extends the life of the seal. In chemical equipment, this means less maintenance costs and longer equipment downtime.

4. Coping with complex working conditions

1. Strong adaptability

The working environment of chemical equipment is often complex and changeable, including changes in temperature, pressure, medium composition and other factors. Graphite Gland Packing can adapt well to changes in these complex working conditions due to its excellent high temperature resistance, high pressure resistance, corrosion resistance and self-lubricating properties. Whether it is stable operation under high temperature and high pressure or long-term work in corrosive media, it can maintain a stable sealing effect.

5. Consumer Guide

1. Choose the appropriate specification and model

When choosing Graphite Gland Packing, consumers should choose appropriate specifications and models based on specific application scenarios and working conditions. Different specifications and models have different sealing performance and application range, so choosing the right product is crucial to ensure the sealing effect.

2. Proper installation and maintenance

Correct installation and maintenance are also important factors in ensuring the sealing effect of Graphite Gland Packing. During the installation process, you should ensure that the fit between the seal and the equipment is tight and leak-free; during use, the status of the seal should be regularly checked and maintained, and aging and damaged parts should be replaced in a timely manner to ensure long-term stable operation of the equipment.

Eng

Eng  русский

русский