As a large comprehensive sealing technology enterprise, we specialize in researching, manufacturing and selling various types of seals, environment-friendly asbestos-free gaskets, specialized rubber material products and parts insulation materials for pneumatic and hydraulic systems.

Customize Service

-

Size & Shape

Customers can customize the size and shape of the seal based on the specific requirements of their equipment or system, ensuring a good fit and good sealing effect. -

Raw-material Selection

Different application environments and media may require seals made of different materials. Customers can choose appropriate materials according to their needs, such as rubber, metal, plastic, composite materials, etc., -

Performance Parameters

Customers may have specific requirements for the performance parameters of seals, such as temperature resistance, pressure resistance, corrosion resistance, etc. Manufacturers need to meet customer needs based on the design and materials of seals. -

Printing Services

Our printing technology allows us to mark and encode various information on many materials to help customers with warehousing, service operations and traceability. -

Parts Traceability

Products can be printed with serial numbers, part and lot numbers, barcodes, and even logos or branding information. For many industries, such as the petrochemical industry, product printing can be an effective way to accelerate discovery. -

Product Packaging

Customers may have specific packaging requirements, such as special packaging materials, packaging methods, or labeling requirements. We can customize packaging according to customer requirements to ensure the safety and integrity of the product.

Technology R&D Capacity

After years of development, we have become a globally renowned provider of overall sealing solutions.

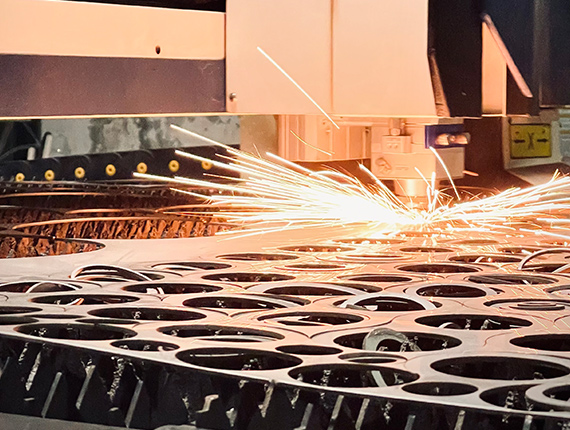

Large Production Capacity

Our company built the project of sealing sealing technology industrial park in 2012 and this project was put into production in December 2013. In this way, we cooperated with many foreign well-known brands, such as Garlock, Flexitallic, Novus(subsidiary agency)and sold their products and many other series of sealing products.

-

● Advanced Laser Cutters

● CNC Tool Table

● Water Jet Machine

● CNC Punch Press

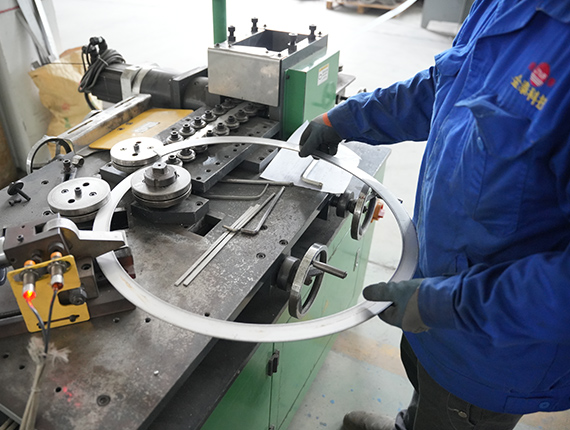

● Spiral Winding Machine

Technological Innovation

Jintai Sealing adhering to the enterprise spirit of "winning in the future", insists on self-making core equipment, and constantly makes innovations.

Our products have achieved the CCS classification society quality system identification, participated in the world Expo in 2010, passed the CiT test for environmental protection and the Chinese Academy of Coal Sciences test, the national nonmetal test, etc.

TECHNICAL SUPPORT

Jintai Sealing has tremendous strength to provide customers with a complete service system.

-

One-stop Sealing Solution Provider More Than 20+ Years

Through continuous innovation and technological improvement, we are committed to providing customers with high-quality customized seals to meet their specific needs and achieve win-win development.

The annealing process uses the principles of thermodynamics to diffuse atoms in the metal and break chemical bonds. Typically, metal is heated to a temperature between 250°C and 750°C over a period of time, depending on the properties of the material. The metal is then slowly cooled, causing it to soften and become more ductile.

Eng

Eng  русский

русский